Tanks made out of mild steel, stainless steel, and poly-lined tanks are approved for use with Axxatec™ DA-24C. DO NOT USE an aluminum tank.

ZERUST® Axxatec™ DA-24C

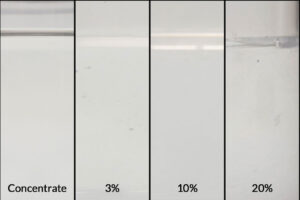

ZERUST®/EXCOR® Axxatec™ (Dual-Action) DA-24C is a water-based, low or no foam, liquid concentrate rust preventative and light-duty cleaner, designed to provide up to 3 months‡ of indoor storage and in-transit protection for ferrous-based alloys, while also being compatible with yellow metals.

Features

- Low or no foaming

- Safe for yellow metals

- Dual-action yellow metal rust preventative and cleaner

- Offers light-duty hydrocarbon soil and particulate cleaning ability

- Oil-splitting performance for longer bath life

- Hard water compatible

- Does not contain chelates, silicates, or phosphates

- Non-flammable

- Leaves an invisible dry-to-touch thin coating

- Water-soluble

- Not regulated for transport or disposal

Product Description

In addition to the corrosion protection offered, Axxatec™ DA-24C yellow metal rust preventative and cleaner is compatible with hard water and provides oil-splitting performance. However, a well-maintained oil skimmer or splitter is essential for clean and contaminant-free parts, as it removes the oil layer (contaminants) from the bath. Although Axxatec™ DA-24C excels in applications where yellow metals are present, Axxatec™ DA-23C is recommended for those needing protection for only ferrous alloys.

When applied and dried, it leaves a safe, clear, dry-to-touch protective coating. As a result, Axxatec™ DA-24C coated and dried parts are safe to handle, and end users do not need to wear personal protective equipment such as a respirator, mask, or safety glasses, making it safer and more economical to use than solvent-based systems. Even though the use of gloves is not mandatory for PPE; we highly recommend using clean gloves without lint or talc while handling parts coated with Axxatec™ DA-24C. This is to prevent leaving corrosive contaminants on the parts.

After allowing metals to completely dry, place them into ZERUST® Vapor Corrosion Inhibitor (VCI) film packaging products for a more robust solution that protects for years‡ during indoor storage or challenging shipping conditions, such as ocean freight. Axxatec™ DA-24C does not contain chelates, silicates, or phosphates, is non-flammable, complies with Global Automotive Declarable Substance, TSCA, SVHC, RoHS, and REACH requirements, and is environmentally friendly.

Why Choose ZERUST®?

For over 50 years, beginning with the invention of Vapor Corrosion Inhibiting (VCI) film, ZERUST® has led the market in quality corrosion solution products. Furthermore, we dedicate ourselves to providing expert corrosion management services and further adding solutions for our customers. In addition, ZERUST® users have access to on-site support from ZERUST®/EXCOR® representatives in more than 70 countries. As a result, our customers have peace of mind when they choose ZERUST® for corrosion control management.

Availability

ZERUST®/EXCOR® Axxatec™ (Dual-Action) DA-24C yellow metal rust preventative and cleaner is sold as a liquid concentration. For further ordering information, contact your ZERUST®/EXCOR® representative.

| Part Number | Substrates | Quantity |

|---|---|---|

| 350-M-00104PL | Protects ferrous-based alloys and yellow metal compatible. | 5 Gallons |

| 350-M-00104DR | Protects ferrous-based alloys and yellow metal compatible. | 55 Gallons |