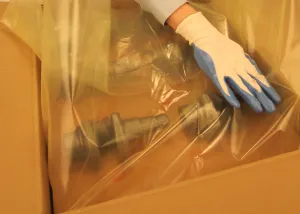

Corrosion solutions engineered for a world of industries

ZERUST®/EXCOR® offers a complete line of corrosion inhibitor packaging and rust solutions. ZERUST® is the inventor of Volatile Corrosion Inhibitor (VCI) poly technology and offers expert on-site support in over 70 countries worldwide. For nearly 50 years, ZERUST® has helped customers reduce the cost and problems associated with corrosion. Have a challenging corrosion prevention need? Trust ZERUST® to help you manage corrosion in your operations.