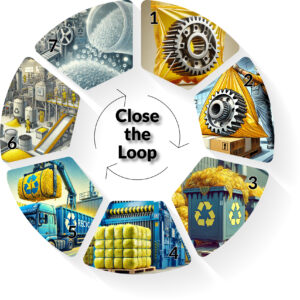

By using ZERUST® VCI packaging and participating in the ZeCycle Recycling Program, your business can significantly minimize plastic waste while maintaining the same trusted corrosion protection. However, by choosing ZERUST® ICT®510-PCR30 VCI packaging and closing the loop with ZeCycle, you can take it a step further—reducing your business’s carbon footprint while supporting a circular economy. Through the ZERUST® and RecycleMax® recycling program, ZeCycle, companies can take measurable steps toward zero waste goals by closing the loop on packaging and incorporating responsible recycling into their operations.

Why Choose ZeCycle?

- Work Towards Zero Waste Goals – Minimize plastic waste by recycling used ZERUST® VCI packaging.

- Lower Carbon Footprint – Reduce emissions using PCR-based ZERUST® ICT®510-PCR30 instead of virgin LDPE film.

- Simplified Recycling – RecycleMax® manages pickup, transport, and processing while training staff on proper recycling and implementing facility-wide recycling processes.

- Cost Savings – Reduce waste disposal costs through on-site recycling.

- Meet Sustainability Goals – Support a circular economy and regulatory compliance initiatives.