Who?

What?

Corrosion management for CKD overseas shipments

Why?

Increase process yields, reduce labor, and costs

How?

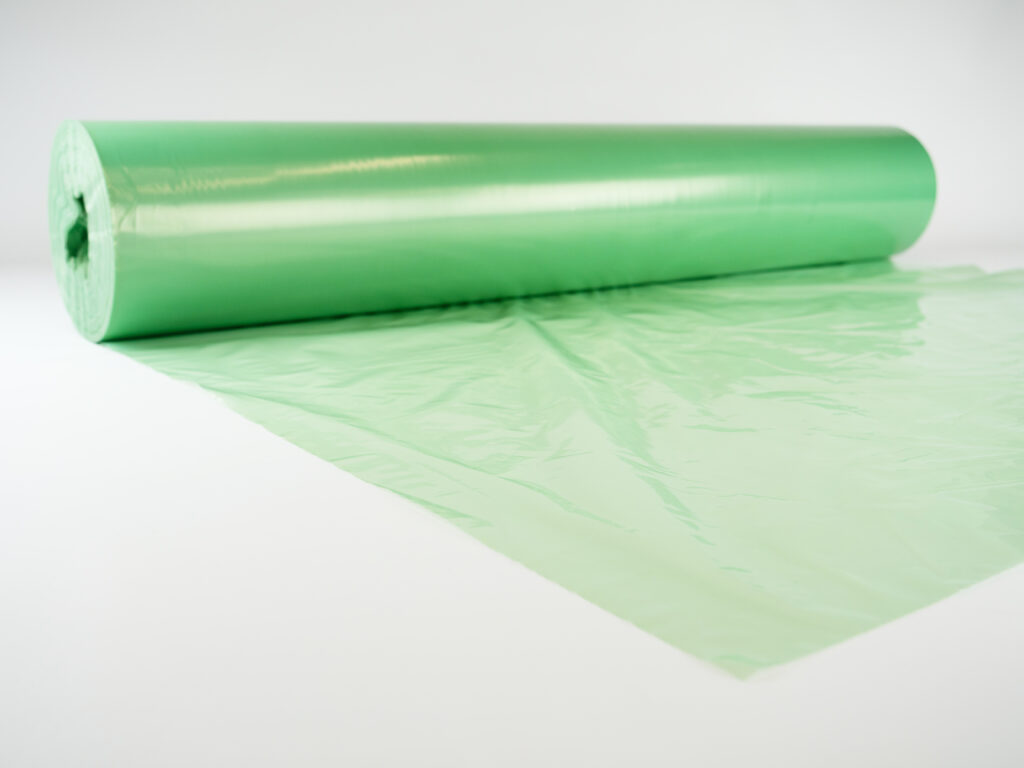

Switching to ZERUST® ICT® 510-C VCI Film protects overseas shipments from corrosion and eliminates messy oils

Corrosion management for CKD overseas shipments

Increase process yields, reduce labor, and costs

Switching to ZERUST® ICT® 510-C VCI Film protects overseas shipments from corrosion and eliminates messy oils

A Russian automaker experienced corrosion on stamped metal surfaces during CKD (complete knock-down) shipments from Russia to Ecuador. They used various oils as their corrosion protection method, which proved to be ineffective and an environmentally hazardous means of protection. The auto manufacturer needed a different solution that would work efficiently and without the contamination and the clean-up that comes with oil.

ZERUST’s international team of corrosion experts recommended ZERUST® ICT®510-C Ferrous and Multimetal VCI Film to protect steel and galvanized steel during transportation and storage. After a successful trial shipment to Ecuador, ZERUST® VCI films were officially approved for use.

Automotive parts protection from rust & corrosion

For years‡

Amount saved by ZERUST® VCI film

$858,000 USD per year

Customer Satisfaction

100%

The manufacturer found that using ZERUST® Vapor corrosion inhibiting (VCI) products paid off. Corrosion stopped completely on stamped parts and anywhere else ZERUST® products were used. In addition, the company eliminated oil as corrosion protection in many production areas, helping improve CKD shipment process yields. Using ZERUST® also reduced costs by eliminating the internal logistics and workforce necessary to remove the oil and clean the parts before they can be used. By using ZERUST® products, they saved US$858,000 per year! Contact a ZERUST® Representative for a comprehensive corrosion management solution most effective for your metal assets.