When Axxanol™ 718-ESS is used as prescribed, substrates tested show no staining, but testing specific metals before use is always recommended.

ZERUST® Axxanol™ 718-ESS

ZERUST®/EXCOR® Axxanol™ 718-ESS is an electrical corrosion inhibitor spray that leaves a thin, water-displacing, non-staining, non-hardening, soft film, providing protection against challenging environments where acid gas vapors and humidity are present.

Features

- Electrical corrosion inhibitor spray that does not interfere with electrical contacts or resistivity

- Leaves a thin, non-hardening, clear coating on surfaces

- Good water displacement characteristics, as well as acid gas, salt spray, and humidity resistance

- UV fluorescence for ease of coverage determination

- Conforms to key aspects of MIL-PRF-81309H

- Protects metals indoors, as well as outdoors

- Not regulated for transport

Product Description

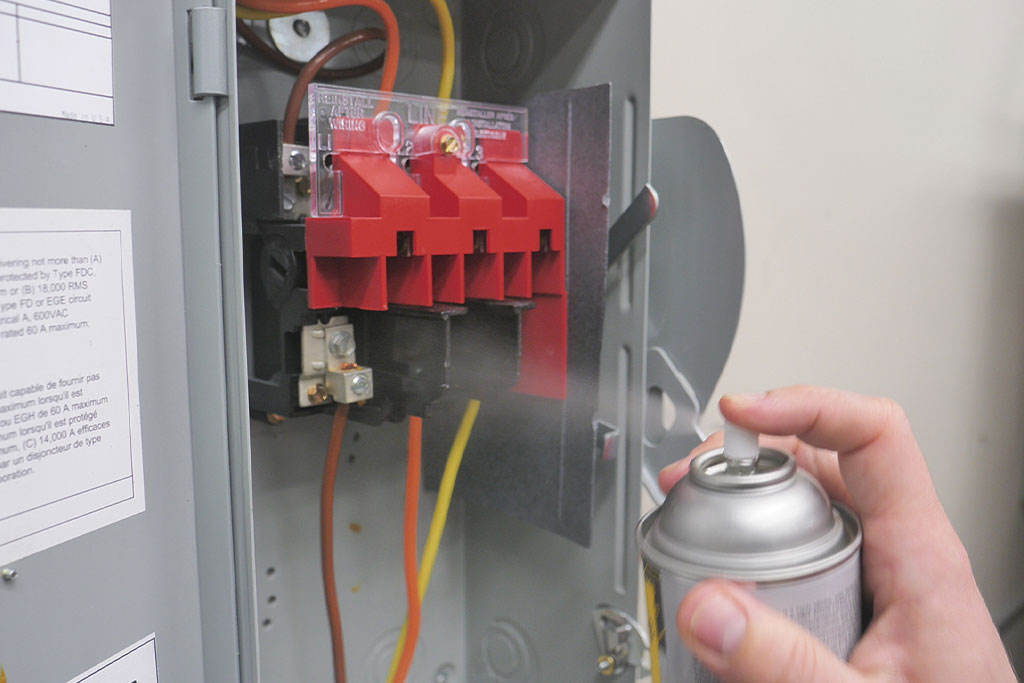

Use Axxanol™ 718-ESS to safely protect electronic components, electric cabinets, junction boxes, and more. In addition to electronic applications, it can be used on any metal surface, such as hinges, machinery, and sliding parts, to provide corrosion protection and lubrication.

Easy to use, suited for in-service use, and intended for indoor and short-term outdoor protection and lubrication. Simply turn off the in-service electronic and apply with the ready-to-use spray bottle or aerosol can. During drying, the solvent completely evaporates. As a result, leaving behind a safe, thin, water-displacing, non-staining, non-hardening, soft film that does not modify the conductivity of electronic components. Additionally, Axxanol™ 718-ESS contains no CFCs or 1,1,1-Trichloroethane and was designed to conform to key aspects of MIL-PRF-81309H.

Why Choose ZERUST®?

For over 50 years, beginning with the invention of Vapor Corrosion Inhibiting (VCI) film, ZERUST® has led the market in quality corrosion solution products. Furthermore, we dedicate ourselves to providing expert corrosion management services and further adding solutions for our customers. In addition, ZERUST® users have access to on-site support from ZERUST®/EXCOR® representatives in more than 70 countries. As a result, our customers have peace of mind when they choose ZERUST® for corrosion control management.

Availability

ZERUST®/EXCOR® Axxanol™ 718-ESS electrical corrosion inhibitor spray is available as a ready-to-use liquid product. For further ordering information, contact your ZERUST®/EXCOR® representative.

| Part Number | Quantity | Protection | |

|---|---|---|---|

| 350-M-00092PT | (12/case) 16 oz spray bottles (w/ spray nozzles) | Multimetal | |

| 350-M-00092AC | (12/case) 12 oz aerosol cans | Multimetal |

Frequently Asked Questions

Yes. However, the surface temperature should not exceed 130°F (54°C) during application as reduced corrosion performance is noted with temperatures above 130°F (54°C).

No, Axxanol™ 718-ESS does not leave a coating that is conducive to paint adhesion. Therefore, surfaces should be thoroughly cleaned with solvent or alkaline cleaners before painting.

You may remove the Axxanol™ 718-ESS coating using mineral spirits or alkaline cleaners and gentle wiping with a lint-free cloth.

Yes, make sure that the surface is free of dirt and/or dust before reapplying. Follow the instructions on the product label for spraying Axxanol™ 718-ESS. NOTE: The reapplication of Axxanol™ 718-ESS won’t revert any corrosion that already exists.

Axxanol™ 718-ESS was designed for protection applications where ZERUST® Vapor Capsules may not provide adequate protection, such as electrical panels, etc., containing air exchange. Since ZERUST® Vapor Capsules protect metals using Vapor Corrosion Inhibitors (VCIs), which slowly release into a sealed air space and form a strong bond with the metal surface, preventing corrosion on the metal surface. As a result, if your enclosure has any air exchange, the VCIs will leave your enclosure and not provide adequate protection, so Axxanol™ 718-ESS should be used to protect your metal assets in these situations.

Since Axxanol™ 718-ESS is a stand-alone corrosion inhibitor product that creates a coating on the metal surface, the VCIs may not reach the metal surface, so it will not provide any additional corrosion protection. However, if there are hard-to-reach metal surfaces that are not coated by Axxanol 718-ESS and are in a sealed enclosure, ZERUST® Vapor Capsules may be used to provide VCI protection to those surfaces.

Yes. However, Axxanol™ 718-ESS is a stand-alone corrosion inhibitor product. If your application requires additional VCI, ZERUST® offers a complete line of Vapor Capsules (e.g., VC1-1(s), VC1-1, VC2-1, VC2-2, VC6-1, VC6-2) that are compatible with Axxanol™ 718-ESS. However, compatibility tests have not been completed with any non-ZERUST® VCI emitter and diffuser products, so it’s recommended to perform compatibility tests before combining Axxanol™ 718-ESS with any non-ZERUST® VCI emitters or packaging products.

Yes, Axxanol™ 718-ESS contains ingredients that may settle over time. Therefore, for Axxanol™ 718-ESS to perform as designed, you must shake well to ensure that these ingredients mix well before use.

Yes, however, the Axxanol™ 718-ESS bottle must be shaken thoroughly before use. At temperatures 25°F (-4°C) and lower, the product will thicken and come out as a stream instead of a spray.

No, the Axxanol™ 718-ESS product has expired and may not provide the intended corrosion protection performance.

Yes, always ensure that the power is off before applying Axxanol™ 718-ESS. If possible, ventilate the area you are applying Axxanol™ 718-ESS to minimize smell and accelerate drying after application.

The Axxanol™ 718-ESS bottle should be positioned 4 – 6” from the clean, dry, and dust-free surface(s) that need protection when spraying a light mist over the surface(s). Allow 10 – 15 minutes for the coating to dry, and apply another light mist after to ensure adequate coverage.

Drying times vary with the thickness of the Axxanol™ 718-ESS applied, the environment temperature, and the surface profile of the coated area. We recommend waiting 15 minutes or longer after the application of Axxanol™ 718-ESS before turning the power back on. Axxanol™ 718-ESS will dry to a soft, oil sheen, non-harden layer. Ideally, parts should be air-dried to ensure an even coating. However, a low-volume fan may be used to shorten drying time. High pressure and heat should be avoided as this can create thin coating areas or cause the solution to sag from the surface while drying.

Corrosion protection periods for electrical components will vary depending on the exposure of the components to the environment. While it is very hard to determine the duration of protection due to multiple factors such as humidity, temperature, acid gas, cleanliness of the metal surfaces, etc., we recommend reapplying Axxanol™ 718-ESS every 6 to 12 months depending on your access to the components.

Axxanol™ 718-ESS will dry to a soft, oil-sheen, non-hardening layer. Drying times vary with the thickness of the Axxanol™ 718-ESS applied, the environment temperature, and the surface profile of the coated area. Typically 15 minutes or longer after application of Axxanol™ 718-ESS would be sufficient, but if the coated surfaces have many recesses and pooling of Axxanol™ 718-ESS, a longer drying time will be required. Ideally, parts should be air-dried to ensure an even coating. However, a low-volume fan may be used to shorten drying time. High pressure and heat should be avoided as this can create thin coating areas or cause the solution to sag from the surface while drying.

Axxanol™ 718-ESS protected steel in acid gas testing up to 130°F (54°C). However, performance was reduced at temperatures ranging between 130-212°F (54-100°C) with minimal protection above 212°F (100°C).

Yes, Axxanol™ 718-ESS can be applied for this purpose for temporary indoor and limited outdoor corrosion protection.

Email sds@ntic.com to request the Safety Data Sheet for Axxanol™ 718-ESS and/or all other ZERUST® products.

Request Information

Please complete the form below to request a sample or information. A ZERUST® representative will review your request and reply within 1 business day.

Related Products

-

Axxanol™ A35CD-7 is a high-flash solvent-based rust preventative that forms a clear, thin, dry-to-touch film. As a result, it eliminates oily surfaces that attract dust and other contaminants.

-

Axxanol™ A35CD-32 is a solvent-based, non-staining rust preventative that forms a clear, thin, near dry-to-touch RP film. As a result, it provides powerful corrosion protection against aggressive environments, such as salt air and humidity.

-

Axxanol™ 33 is a rust preventative oil that forms a light oily film, providing powerful corrosion protection against aggressive environments such as salt air and humidity.

-

Axxanol™ 46-BIO is a sprayable bio-based rust preventative oil that forms a thin, transparent, non-tacky film that’s also a light lubricant oil.

-

Axxanol™ 34CD is a solvent-based coating that forms a very light, oily, near dry-to-touch rust preventative film that provides powerful corrosion protection against aggressive environments.

-

Axxanol™ 750 is a rust prevention spray containing Vapor Corrosion Inhibitors (VCI). When shipped or stored in enclosed packaging, Axxanol™ 750 forms a clear, thin, oily film that provides a moisture barrier and contact inhibitor with ZERUST® VCI chemistry that migrates to metal surfaces in hard-to-reach voids, crevices, and chambers, providing powerful corrosion protection.

-

Axxanol™ 750-NV is a rust preventative oil that forms a clear, thin, oily film on the metal surface, providing a moisture barrier and powerful corrosion protection against aggressive environments such as salt air and humidity.

-

Axxanol™ Spray-G is a sprayable rust preventative grease that provides the protection of a grease in the convenience of a sprayable form. It’s designed to protect metal parts, equipment, and assemblies during long-term indoor and outdoor storage and challenging overseas shipping applications where a removable coating is essential.

-

Axxanol™ Z-Maxx Anti-Corrosion Grease Series consists of two products, Axxanol™ Z-Maxx and Z-Maxx LV. Z-Maxx is a thick NLGI 2 grease and is also offered as a lower viscosity (LV) NLGI 0 grease that is designed for spreadability and light lubrication properties.

-

Axxatec™ 80C is a water-based liquid concentrate rust preventative designed to provide long-lasting protection during indoor storage, shipping, and assembly.

-

Axxatec™ 8110C is an easy-to-use water-based corrosion-inhibiting additive for the protection of interior surfaces and parts comprised of iron, steel, aluminum, copper, and brass within closed systems.

-

Axxatec™ 85-F is a ready-to-use water-based VCI rust preventative liquid designed for fogging and spraying applications. It protects ferrous metals using ZERUST® contact inhibitors and proven Vapor Corrosion Inhibitor (VCI) technology.

-

Axxatec™ 87-M is a ready-to-use foggable water-based rust preventative designed for fogging and spraying applications. It protects ferrous metals using ZERUST® contact inhibitors and proven Vapor Corrosion Inhibitor (VCI) technology and is multimetal compatible.

-

AxxaVis™ HST-10 powder additive is an effective hydrostatic testing corrosion inhibitor that treats water used to test pressure vessels and voids. It reduces hardness and deactivates ionic contaminants like chlorides found in municipal water sources, preventing rust and hard water deposits on metals.

-

AxxaVis™ PX-05-AN is a powder that, when added to rinse water, enables it to neutralize acids left by cleaning processes. Use to control flash corrosion on metals caused by acids left over from cleaning and rust removal treatments, such as ZERUST® AxxaClean™ rust removers.

-

AxxaVis™ PX-10-HRD is a powder metalworking fluid additive that conditions hard water when deionized water is unavailable. Use to treat tap water with a hardness of up to 700 ppm CaCO3 and prevent scale and scum. In addition, it increases the performance of ZERUST® products that require dilution, such as Axxatec™ and AxxaWash™ concentrates.

-

Axxanol™ A35CD-7 is a high-flash solvent-based rust preventative that forms a clear, thin, dry-to-touch film. As a result, it eliminates oily surfaces that attract dust and other contaminants.

-

Axxanol™ A35CD-32 is a solvent-based, non-staining rust preventative that forms a clear, thin, near dry-to-touch RP film. As a result, it provides powerful corrosion protection against aggressive environments, such as salt air and humidity.

-

Axxanol™ 33 is a rust preventative oil that forms a light oily film, providing powerful corrosion protection against aggressive environments such as salt air and humidity.

-

Axxanol™ 46-BIO is a sprayable bio-based rust preventative oil that forms a thin, transparent, non-tacky film that’s also a light lubricant oil.