When it comes to corrosion prevention during shipping and storage, two common methods are often discussed: Vapor Corrosion Inhibitors (VCIs) and desiccants. Although both aim to protect metal surfaces, their mechanisms and ideal applications differ significantly. Understanding these differences can help you choose the most effective solution based on your specific needs, environment, and duration of protection. In some cases, a combination of both VCIs and desiccants may offer optimal results. Let’s delve into how these two solutions work and when each is most appropriate.

Desiccants

Desiccants function by absorbing and retaining moisture from the surrounding environment, thereby reducing the amount of water available to react with metal surfaces. This moisture absorption helps in preventing corrosion by lowering the humidity levels in the protected area. Various types of desiccants have different absorption capacities, operational temperatures, and other characteristics. However, they all share a common limitation: once a desiccant becomes saturated, it can no longer absorb moisture and may even release the absorbed water back into the air, potentially increasing the corrosion risk. Therefore, it is crucial to monitor and replace desiccants regularly to maintain effective corrosion protection.

Advantages

- Cost-Effective: Desiccants are generally inexpensive and accessible.

- Safe and Environmentally Friendly: They are clean, dry, and pose minimal environmental or health risks.

- Ease of Use: Desiccants are simple to apply and require minimal labor.

Volatile/Vapor Corrosion Inhibitors (VCIs)

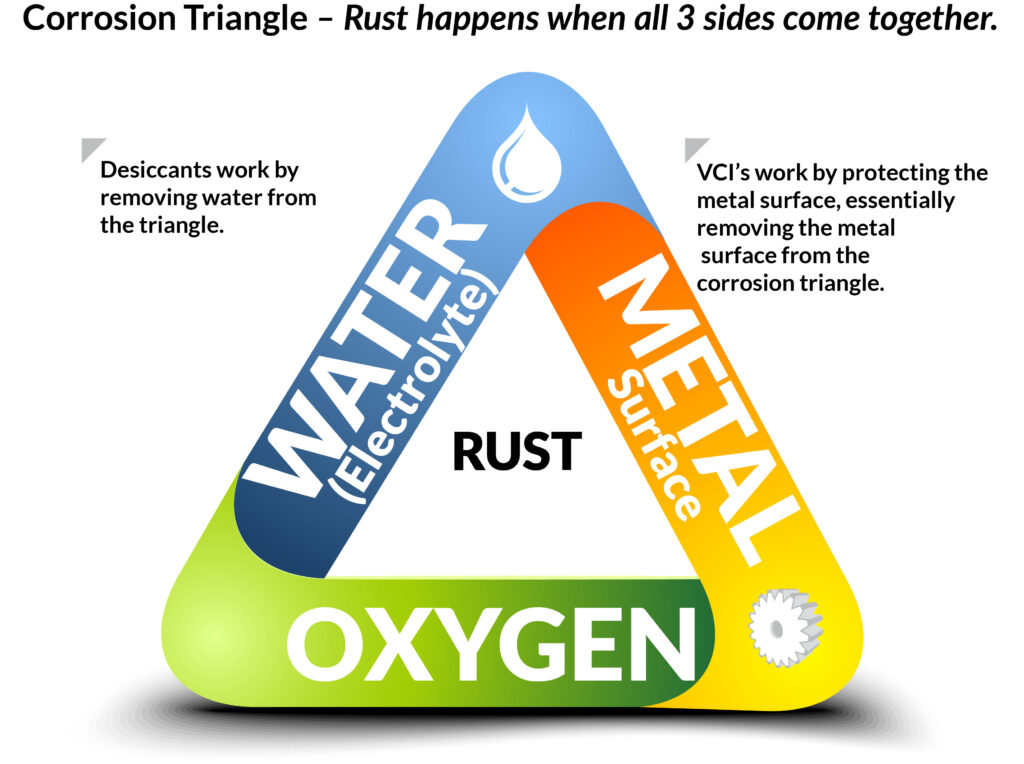

VCIs, or Vapor Corrosion Inhibitors, offer a more advanced solution to corrosion prevention. VCIs release vapor-phase molecules that diffuse throughout an enclosed space, forming a protective molecular layer on metal surfaces. This layer not only prevents direct contact between the metal and corrosive agents but also helps maintain the metal’s natural passive oxide layer, which is crucial for preventing corrosion.

Unlike desiccants, VCIs do not rely on moisture absorption; instead, they work by chemically bonding with the metal surface to inhibit the electrochemical reactions that cause rust. VCIs are available in various forms, including poly packaging, kraft paper, emitters, and powders, and are effective for both ferrous and non-ferrous metals.

Technical Insights

VCIs operate based on the principles of inorganic chemistry, particularly ligand field theory. This theory explains how VCIs form coordinate covalent bonds with metal cations, stabilizing them by sharing electrons and slowing down the oxidation process. Essentially, VCIs disrupt the natural rusting process by interfering with the oxidation reactions at a molecular level.

Advantages

- Long-lasting Protection: VCIs provide extended corrosion protection, often lasting for years.

- Non-Invasive: The protective layer formed by VCIs is invisible, dry, and does not require removal before using the metal.

- Versatile Applications: VCIs are suitable for a wide range of metals and can be customized to meet specific protection needs.

- Labor and Cost Savings: By eliminating the need for regular maintenance and the application of rust preventatives, VCIs reduce labor costs and overall expenses.

VCI vs Desiccant: When to Use Each

Choosing between VCIs and desiccants depends on several factors, including the type of metal, the environmental conditions, and the duration of storage or shipment. Desiccants are ideal for environments where moisture control is the primary concern, especially in short-term applications. However, for longer-term protection or in situations where it is impractical to replace desiccants regularly, VCIs offer a more robust and reliable solution.

In many cases, combining VCIs with desiccants can provide comprehensive protection. For instance, a packaging system could use a VCI gusset bag to protect the metal while adding a desiccant to manage moisture levels during transit. This combination ensures that both humidity and corrosion are controlled, providing a multi-layered defense against rust.

Conclusion

At ZERUST®, we understand the complexities of corrosion prevention and offer tailored solutions to meet your specific needs. Our Technical Support team is equipped to analyze your current processes and recommend the most effective and cost-efficient solutions. Whether you need desiccants, VCIs, or a combination of both, ZERUST® is here to help you protect your valuable assets from corrosion. Contact us today for a comprehensive evaluation of your corrosion management strategy.