Part cleaning is an essential step in the manufacturing process, as precision metal parts typically have oils, greases, and other lubricants on the surface after the part is manufactured. These residues can prevent the adhesion of coatings and paints and accelerate corrosion if not properly removed. Manufacturers understand the importance of delivering clean parts in the supply chain process, but they also understand how important it is to have cost-effective cleaning solutions. While the actual cleaning process is an expense to the manufacturers, this cost is minimal compared to the cost of reworking or having to reproduce new parts due to a rejected shipment. That’s why these manufacturers deploy different cleaning processes, depending on the metal part being produced. Common cleaning processes include: immersion cleaning, spray cleaning, wet vapor blasting, vapor honing, ultrasonic cleaning, hand cleaning, and vibrating tumbler.

ZERUST® has a wide array of products to further enhance these cleaning processes by cutting the total time to clean the part, enhancing the cleaning and adhesion, and also providing additional corrosion protection to prevent corrosion during shipping/storage. Below you will find the recommended ZERUST® products that will enhance each of the common cleaning processes and provide cost savings by cutting labor, cost of rework, and minimizing part rejections.

IMMERSION CLEANING

Immersion cleaners are engineered to be powerful, efficient, and economical in descaling and degreasing compounds. They are specially formulated to effectively remove straight oils, soluble oils, metalworking fluids, metal-forming lubricants, carbon scale, heavy soils, and dirt, as well as tramp oils and greases from ferrous and non-ferrous metals and associated alloys. ZERUST® offers AxxaWash™ NW-10 /NW-12 that deactivate ionic contaminants and prevents flash corrosion after cleaning. These cleaners can be used in conventional spray cleaning equipment as well as high to UHP (Ultra High Pressure jetting equipment.

- AxxaWash™ NW-10 – Alkaline cleaner that deactivates common corrosion-inducing anionic contaminants and prohibits flash corrosion after cleaning.

- AxxaWash™ NW-12 – Alkaline cleaner that deactivates common corrosion-inducing anionic contaminants and provides short-term corrosion prevention after cleaning.

- AxxaClean™ 2048 Immersion – Organic acid-based rust remover for light-medium duty rust.

- AxxaClean™ 3048 Immersion – Phosphoric-based rust remover for medium – heavy duty rust.

- AxxaClean™ CR-20 – Fast, very effective carbon removal.

SPRAY CLEANING

Spray cleaners are engineered to be powerful, efficient, and economical in descaling and degreasing compounds. They are specially formulated to effectively remove straight oils, soluble oils, metalworking fluids, metal-forming lubricants, carbon scale, heavy soils, and dirt, as well as tramp oils and greases from ferrous and non-ferrous metals and associated alloys. ZERUST® offers AxxaWash™ NW-10 that deactivates ionic contaminants and prevents flash corrosion after cleaning.

- AxxaWash™ NW-10 – Alkaline cleaner that deactivates common corrosion-inducing anionic contaminants and prohibits flash corrosion after cleaning.

- AxxaWash™ NW-12 – Alkaline cleaner that deactivates common corrosion-inducing anionic contaminants and provides short term corrosion prevention after cleaning.

- AxxaClean™ 2048 Spray and Brush-on – Organic acid-based rust remover for light-medium duty rust. Safe for operators and the environment.

- AxxaClean™ 3048 Brush-On – Phosphoric-based rust remover for medium – heavy duty rust.

- AxxaClean™ CR-20 – Fast, very effective carbon removal.

WET VAPOR BLASTING

Wet vapor blasting is a very powerful, efficient, and economical to use method of cleaning and corrosion product removal. Wet vapor blasting consists of pressured water in combination with abrasive media such as (sand, glass, walnut, etc.) which is used to effectively remove coatings, contaminants, corrosion, and residues from hard surfaces. ZERUST® offers AxxaVis™ WBA-10 that counters corrosive anions on metal surfaces while also providing flash corrosion inhibition to protect the surface after cleaning for extended periods of time. AxxaVis™ WBA-10 is hard water capable.

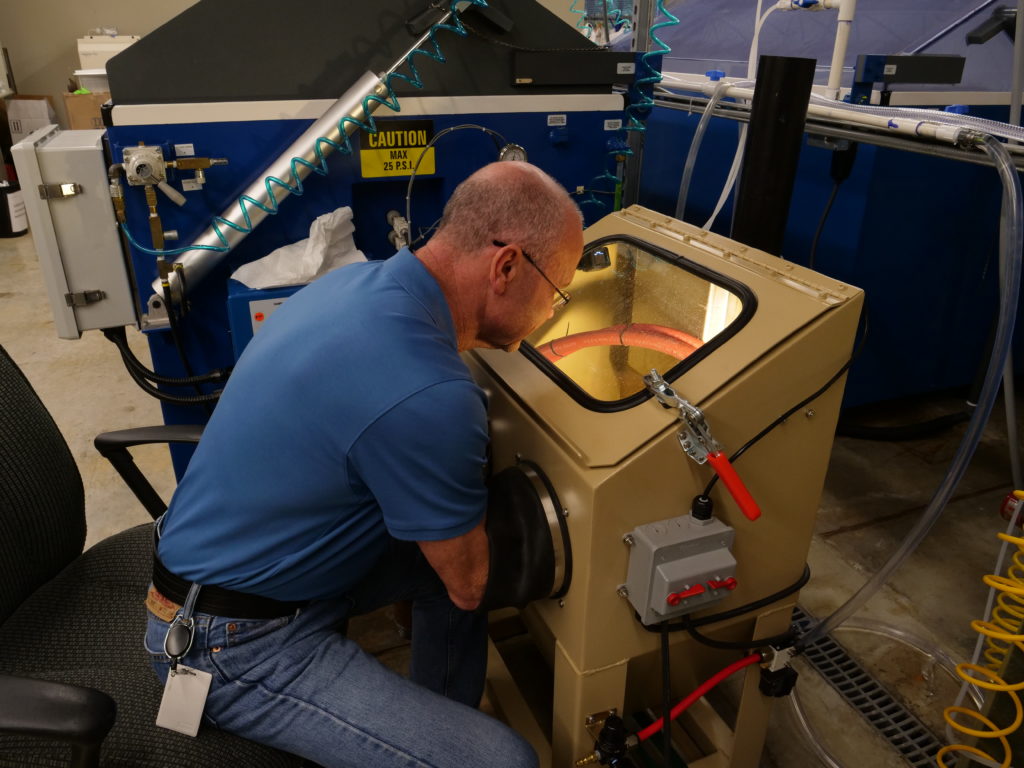

VAPOR HONING

Vapor honing is very similar to wet vapor blasting as it uses a combination of pressured water with abrasive media such as (sand, glass, walnut, etc.) to effectively remove coatings, contaminants, corrosion, and residues from hard surfaces. However, vapor honing is a more scaled-down process as it is commonly found in a smaller cabinet. So, this process works well when removing coatings, contaminants, corrosion, and residues for smaller machined parts. ZERUST® offers AxxaVis™ WBA-10 that treats corrosion-causing chlorides and hardness of the water on a metal surface while also providing a flash corrosion inhibitor to protect the surface after cleaning.

Advantages of Vapor Honing:

- Dust-free process

- Cleans by a flow of water/cleaner and media impact

- Simultaneously degrease & blast clean

- Water acts as a lubricant between media & component

- Promotes longer media life

- Produces a ‘softer’ finish

- Avoids media impregnation on soft materials

ULTRASONIC CLEANING

Ultrasonic cleaners are formulated to be formidable, highly efficient, and very economical. By design, ultrasonic washers generate cavitation throughout the solution by emitting ultrasound waves, helping to loosen soils without the use of high-pressure spray nozzles. Ultrasonic cleaners are formulated specifically for this form of operation with advanced-technology detergency additives engineered to remove straight oils, soluble oils, metal-forming lubricants, metalworking fluids, coolants, buffing and polishing compounds, calcium soaps, waxes, tramp oils, greases, metallic smut, dirt and other heavy soils from the surfaces of ferrous and non-ferrous metals. Comprised of potent wetting, loosening, and dispersing properties for fast, effective removal of soils at low operating temperatures and reduced exposure times, they allow for increased rates of production while lowering operating costs. ZERUST® offers:

- AxxaWash™ NW-10 – Alkaline cleaner that deactivates common corrosion-inducing anionic contaminants and prohibits flash corrosion after cleaning.

- AxxaClean™ 2048 Immersion – Organic acid-based rust remover for light-medium duty rust. Safe for operators and the environment.

- AxxaClean™ 3048 Immersion – Phosphoric-based rust remover for medium – heavy duty rust.

- AxxaClean™ CR-20 – Fast, very effective carbon removal.

HAND CLEANING

Hand cleaning can be very labor intensive, time-consuming, and expensive for manufacturers. Whenever you have employees hand washing machined parts, you typically do not have consistent results, while some parts may end up clean, you may find other parts are dirty with contaminants that may cause corrosion. ZERUST® offers AxxaClean™ 2048 in spray-on, brush-on, and immersion applications that allow easy hand cleaning solutions while proving fast-acting rust and tarnish remover that also inhibits flash corrosion after cleaning.

- AxxaWash™ NW-10 – Alkaline cleaner that deactivates common corrosion-inducing anionic contaminants and prohibits flash corrosion after cleaning.

- AxxaClean™ 2048 Spray and Brush-on – Organic acid-based rust remover for light-medium duty rust. Safe for operators and the environment.

- AxxaClean™ 3048 Brush-On – Phosphoric-based rust remover for medium – heavy duty rust.

- AxxaClean™ CR-20 – Fast, very effective carbon removal.

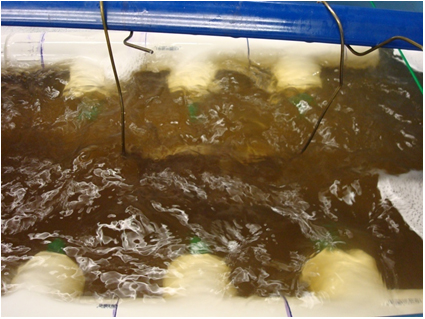

VIBRATING TUMBLER

A vibratory tumbler is a compact machine that is designed to clean, remove scale and corrosion products, polish and deburr smaller metal parts with rapid vibrating action. By gently vibrating and tumbling the parts and tumbling media from bottom to top and from center to the outside edges, cleaning, rust/scale removal, polishing, and deburring of the part surface is effectively accomplished without changing the shape of the parts. Vibratory Tumbling is perfect for various shapes and types of parts using either wet or dry polishing media. To further enhance tumbler cleaning, ZERUST® offers:

- AxxaWash™ NW-10 – Alkaline cleaner that deactivates common corrosion-inducing anionic contaminants and prohibits flash corrosion after cleaning.

- AxxaClean™ 2048 Immersion – Organic acid-based rust remover for light-medium duty rust. Safe for operators and the environment.

- AxxaClean™ 3048 Immersion – Phosphoric-based rust remover for medium – heavy duty rust.

- AxxaClean™ CR-20 – Fast, very effective carbon removal.

- AxxaVis™ HST-10 – Effective against corrosive anions with prolonged flash corrosion inhibition.

Whichever cleaning process your company deploys, ZERUST® can help you by enhancing the corrosion protection of your metal assets. We will analyze the current state of your corrosion management needs and work with you and your team to implement the best and most cost-effective solution. ZERUST® can come to your facility and do a step-by-step analysis of your current process, including fluid audits, VCI and packaging process audits, and data logger analysis. Our mission is to provide you with the right products, processes, and procedures to ensure that you can achieve your desired results.