Introduction to Aqueous Parts Washing

In industrial and automotive maintenance, cleaning parts efficiently while minimizing environmental impact is a critical concern. Aqueous parts washers have emerged as the superior solution, offering effective cleaning with a focus on sustainability. Unlike traditional solvent-based systems, aqueous cleaning relies on water-based detergents, mechanical agitation, and heat to remove contaminants without generating harmful emissions.

What is an Aqueous Parts Washer?

Aqueous parts washers are specialized cleaning systems that use water-based solutions combined with surfactants, emulsifiers, and agitation methods to remove grease, oils, and debris from metal and plastic components. These systems operate through various cleaning mechanisms:

- Spray Washers – Utilize high-pressure water jets to clean parts efficiently.

- Immersion Cleaners – Submerge parts in a cleaning solution, often with ultrasonic waves for deeper penetration.

- Rotary Basket Systems – Rotate parts within the cleaning chamber to ensure thorough coverage.

- Ultrasonic Cleaners – Use high-frequency sound waves to agitate cleaning solutions and dislodge contaminants at a microscopic level.

Aqueous cleaning is recognized for its ability to provide high-performance cleaning while significantly reducing hazardous waste and VOC emissions.

Aqueous Cleaning vs. Solvent-Based Cleaning

Key Differences

| Feature | Aqueous Cleaning | Solvent-Based Cleaning |

|---|---|---|

| Cleaning Agent | Water-based detergents | Chemical solvents (e.g., trichloroethylene, perchloroethylene) |

| Environmental Impact | Low emissions, biodegradable waste | High VOC emissions, hazardous waste generation |

| Occupational Safety | Reduced exposure risks | Can cause respiratory and skin issues |

| Waste Disposal | Easier, less regulated | Strictly regulated, hazardous waste disposal required |

| Operating Costs | Lower long-term costs | Higher due to chemical purchases and waste disposal |

Why Choose Aqueous Over Solvent Cleaning?

- Health & Safety: Solvent-based cleaners pose significant health risks due to their toxic and volatile nature, whereas aqueous cleaning reduces exposure to harmful chemicals.

- Regulatory Compliance: Aqueous systems help companies avoid stringent environmental regulations associated with solvent-based cleaning.

- Operational Savings: While initial investments in aqueous cleaning equipment may be higher, long-term cost savings on solvents, hazardous waste disposal, and regulatory fines make it the more economical choice.

Understanding the Chemistry Behind Aqueous Parts Washing

-

Surfactants

Surfactants play a critical role in aqueous cleaning by reducing surface tension and emulsifying grease and oils. These are categorized into:

- Anionic Surfactants: Effective at breaking down grease and dirt.

- Non-Ionic Surfactants: Commonly used in environmentally friendly formulations due to their biodegradability.

- Amphoteric Surfactants: Provide mild cleaning with corrosion resistance.

-

Builders & Alkalinity Regulators

Builders enhance cleaning performance by softening water and increasing alkalinity. Common types include:

- Sodium Hydroxide & Potassium Hydroxide: Effective degreasers but can be harsh on some metals.

- Silicates: Provide corrosion protection while aiding in emulsification.

- Carbonates & Phosphates: Improve buffering capacity and detergency.

-

Corrosion Inhibitors

Since aqueous cleaning involves water, the risk of rust formation must be managed. Anti-corrosion inhibitors help protect metal parts post-cleaning.

Environmental and Economic Advantages of Aqueous Cleaning

Environmental Benefits of Aqueous Parts Washers

- Reduced Air Pollution: Unlike solvent-based cleaning, aqueous systems release little to no volatile organic compounds (VOCs), improving air quality.

- Minimized Hazardous Waste: Spent aqueous solutions can be treated and often reused, reducing landfill waste.

- Water Conservation: Many modern systems incorporate filtration and recycling, significantly reducing water consumption.

Economic Benefits of Aqueous Parts Washers

- Lower Disposal Costs: Hazardous waste disposal from solvent cleaning is costly; aqueous systems avoid this expense.

- Operational Efficiency: Automated aqueous washers reduce labor costs while improving cleaning consistency.

- Regulatory Compliance: Avoid fines and regulatory complications associated with solvent-based alternatives

Best Practices for Maximizing Aqueous Washer Efficiency

-

Selecting the Right Aqueous Part Washer for Your Needs

- Batch vs. Inline Processing: Choose batch washers for low-volume applications and inline systems for high-throughput operations.

- Agitation Type: Match cleaning intensity to contaminant levels—ultrasonic for delicate parts, spray for heavy grease.

- Heating Element: Hot aqueous solutions clean more effectively, but temperature-sensitive materials may require lower heat settings.

-

Optimizing Chemical Formulations

- pH Balance: Ensure detergents match the material composition to prevent corrosion.

- Surfactant Selection: Tailor formulas for optimal grease and debris breakdown.

- Rinse Stages: Implement a post-cleaning rinse to remove detergent residues.

-

Maintenance and Waste Management

- Regular Filtration: Extend solution life by filtering out particulates and oils.

- Scheduled Drainage & Refill: Prevent solution degradation by maintaining consistent replacement cycles.

- Oil Skimmers & Coalescers: Remove floating oil layers to preserve cleaning efficiency.

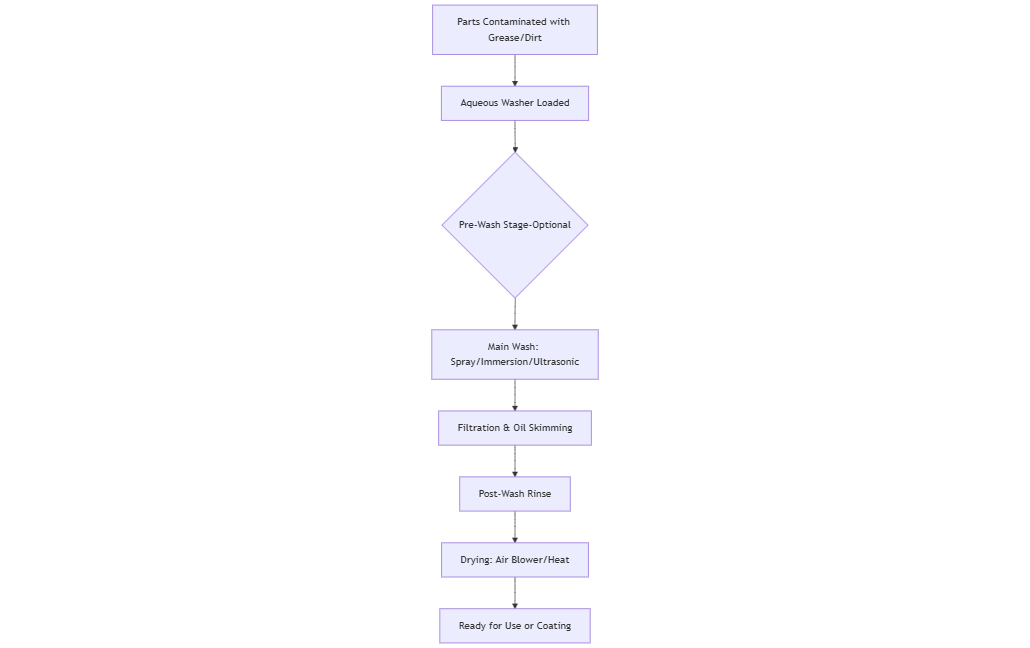

Aqueous Cleaning Process Flowchart

Conclusion: Aqueous Parts Washers as the Future of Industrial Cleaning

Aqueous parts washers provide an eco-friendly, cost-effective, and highly efficient method of cleaning industrial and automotive components. With advancements in chemistry, filtration, and automation, these systems continue to improve, offering superior performance over traditional solvent-based methods. By implementing aqueous cleaning technology, businesses not only enhance cleaning efficiency but also ensure compliance with environmental regulations while promoting worker safety.

For industries seeking a sustainable and highly effective cleaning solution, aqueous parts washers remain the optimal choice.