Sustainable VCI Solutions: A Step Toward Reducing Carbon Emissions

Reducing carbon emissions is a global priority. Businesses are seeking innovative solutions to minimize their environmental impact. ZERUST®, a division of Northern Technologies International Corporation (NTIC), is leading the way with sustainable Vapor Corrosion Inhibitor (VCI) technologies. These solutions extend the life of metal components, reduce waste, and lower reliance on hazardous materials, contributing to a cleaner environment.

Commitment to Sustainability and Reducing Carbon Emissions

ZERUST® is deeply committed to environmental responsibility. The company offsets 100% of its electricity consumption in the U.S. with renewable energy credits. This effort alone eliminates approximately:

ZERUST® is deeply committed to environmental responsibility. The company offsets 100% of its electricity consumption in the U.S. with renewable energy credits. This effort alone eliminates approximately:

- 380 metric tons of CO₂ annually

- The equivalent of 81.8 passenger cars driven for a year

- Energy usage of 47.8 average households for a year

Beyond renewable energy, ZERUST® actively supports green manufacturing by developing technologies that reduce environmental harm and promote energy efficiency.

ZeCycle Recycling Program: Closing the Loop on Plastic Waste

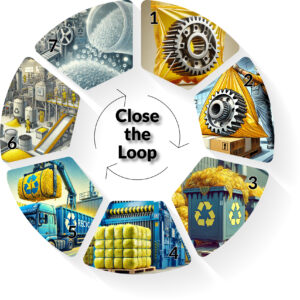

A key initiative in reducing carbon emissions is the ZeCycle Recycling Program, a partnership between ZERUST® and RecycleMax®. This program creates a closed-loop recycling system for used VCI and LDPE packaging. By transforming post-consumer waste into new ZERUST® PCR films, the program significantly reduces landfill waste and lowers reliance on virgin plastics.

How ZeCycle Works

- Metal parts are shipped using ZERUST® VCI packaging.

- The recipient sorts and bales the used packaging.

- RecycleMax® collects and transports the material to a recycling facility.

- The packaging is processed into post-consumer recycled (PCR) pellets.

- These pellets are used to manufacture new ZERUST® ICT®510-PCR30 VCI packaging.

By participating in ZeCycle, companies contribute to the circular economy, reduce plastic waste, and lower their carbon footprint.

Environmental Benefits of ZERUST VCI Products

1. Reducing the Use of Hazardous Chemicals

Traditional rust prevention methods often require oil- or solvent-based coatings, which release volatile organic compounds (VOCs). ZERUST® VCI technology eliminates the need for these hazardous substances, making it a safer and more eco-friendly alternative.

2. Extending the Lifespan of Metals

Corrosion leads to metal waste and increased production demand, both of which have a high environmental impact. ZERUST® protects metals from rust, reducing the need for frequent replacements and cutting down CO₂ emissions associated with new metal production.

3. Minimizing Industrial Waste

The ZeCycle program, combined with VCI protection, reduces landfill waste and scrap metal. Companies adopting ZERUST® solutions can actively contribute to sustainability by reducing disposal and raw material consumption.

4. Lowering Energy Consumption

By preventing rust, ZERUST® ensures metal components last longer, operate efficiently, and require fewer replacements. This leads to significant energy savings in manufacturing and maintenance, further reducing industrial carbon emissions.

5. Supporting a Circular Economy

ZERUST® VCI poly films and papers are fully recyclable, and the ZeCycle program ensures used poly materials are repurposed into new packaging products. This approach conserves resources and significantly reduces the demand for new plastic production.

Green VCI: A Safe and Sustainable Solution for Reducing Carbon Emissions

ZERUST® is committed to safe, non-toxic corrosion prevention. All products comply with major global health and safety regulations, including:

|

|

|

|

|

|

|

|

Reducing Carbon Emissions Through Remanufacturing and Waste Prevention

Remanufacturing is a powerful sustainability tool, and ZERUST® plays a vital role in preserving valuable components. Industrial remanufacturing refurbishes engines, transmissions, and machinery, preventing them from becoming waste. This process saves energy and reduces CO₂ emissions significantly. For example, recycling one pound of steel conserves enough energy to power a 60-watt light bulb for over a day.

Conclusion: ZERUST®’s Role in Reducing Carbon Emissions for a Sustainable Future

Choosing ZERUST® means choosing sustainability. By leveraging VCI technology, the ZeCycle Recycling Program, and energy-efficient corrosion prevention methods, businesses can actively participate in reducing carbon emissions. Investing in ZERUST® solutions not only protects valuable assets but also supports the global effort to combat climate change.

Would you like to learn more about how ZERUST® can help your business reduce its carbon footprint? Contact us today!