Articles by Tom White

Page 3 of 3

Corrosion Solutions for Hydrostatic Testing

Hydrostatic testing of pressure vessels, such as pipes, heat exchangers, storage tanks, and ship voids, is essential for verifying the integrity of these components post-production and during use. This process demonstrates that the equipment can handle operational pressures safely, identifying any potential weak points needing repair. The procedure typically involves raising the internal pressure above

Enhance Your Part Cleaning With the Use of ZERUST® Products

Part cleaning is an essential step in the manufacturing process, as precision metal parts typically have oils, greases, and other lubricants on the surface after the part is manufactured. These residues can prevent the adhesion of coatings and paints and accelerate corrosion if not properly removed. Manufacturers understand the importance of delivering clean parts in

ZERUST® VCI Film Additives & Custom Options

ZERUST®/EXCOR® (Vapor or Volatile Corrosion Inhibitor) VCI film, poly bags, and tubing are produced using a process known as blown film extrusion. The polyethylene is melted and extruded into sheeting which is then slit, folded, or sealed to the desired size and dimensions. With ZERUST’s vast manufacturing network, we have over 100 extrusion lines in

Does Corrugated Affect Corrosion & What Can You Do About It?

When shipping metal parts in cardboard corrugated boxes, do you allow the unprotected parts to touch the box? If so, then the corrugated may be the source of the corrosion. When cardboard boxes are manufactured, the paper begins as pulp and is then dissolved using nitric acid. In order to neutralize the acid before forming

VCI Poly vs VCI Paper? The Advantages and Disadvantages Explained

Volatile Corrosion Inhibitors (VCIs) have been around since the 1940’s, when a product named Dichan was introduced into market. Dichan consisted of dicyclohexylamine-nitrite, which was described as a vapor phase corrosion inhibitor that had sufficient vapor pressure to release corrosion inhibiting molecules into the surrounding area. Eventually, this chemistry began to be coated onto paper,

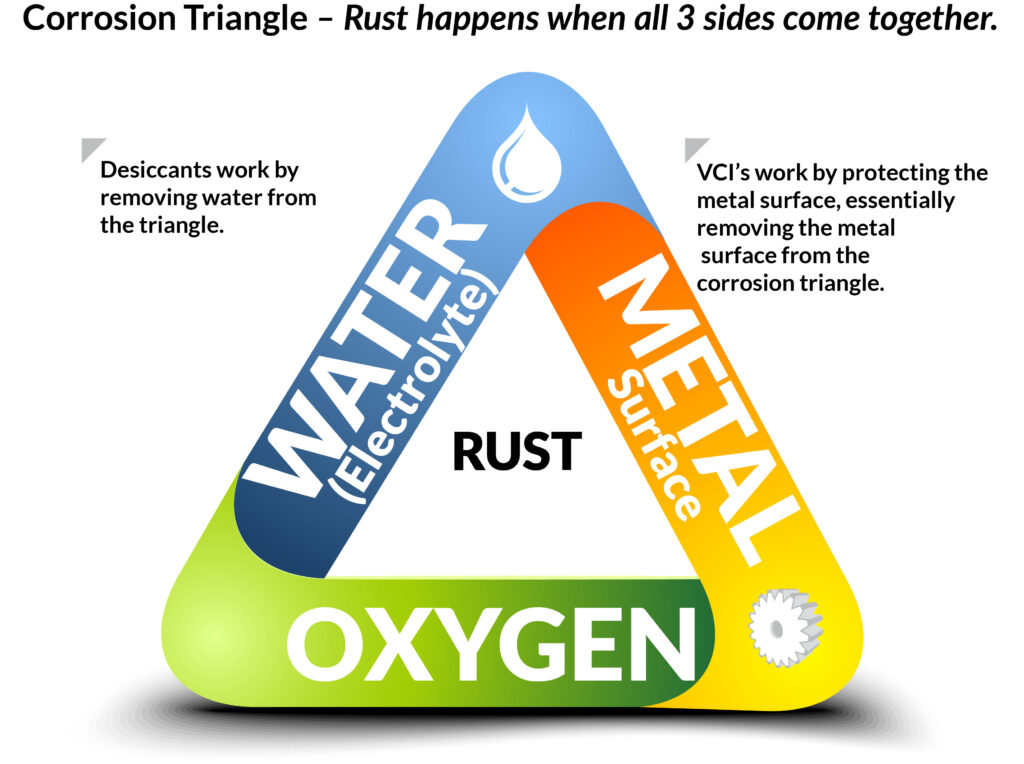

VCIs vs Desiccants. How do they Differ?

When it comes to corrosion prevention during shipping and storage, two common methods are often discussed: Vapor Corrosion Inhibitors (VCIs) and desiccants. Although both aim to protect metal surfaces, their mechanisms and ideal applications differ significantly. Understanding these differences can help you choose the most effective solution based on your specific needs, environment, and duration