How ZERUST® Helps in Reducing Carbon Emissions

Sustainable VCI Solutions: A Step Toward Reducing Carbon Emissions Reducing carbon emissions is a global priority. Businesses are seeking innovative solutions to minimize their environmental impact. ZERUST®, a division of Northern Technologies International Corporation (NTIC), is leading the way with sustainable Vapor Corrosion Inhibitor (VCI) technologies. These solutions extend the life of metal components, reduce

Chloride Neutralization: Protecting Equipment from Salt-Induced Corrosion with ZERUST® AxxaVis™ HST-10 & Axxatec™ HST-20L

Equipment exposed to salt faces a major risk—corrosion. Industries such as mining, marine, and road maintenance often struggle with rust caused by chloride contamination. To combat this, ZERUST® AxxaVis™ HST-10 and Axxatec™ HST-20L offer powerful Chloride neutralization. These products remove corrosive salts, prevent rust, and extend equipment life. The Impact of Chloride Contamination on Equipment

Corrosion Prevention for Power Generation: Protecting Critical Equipment

Power generation facilities operate in harsh and demanding environments, making corrosion prevention for power generation a critical concern. Components in biomass energy plants, hydroelectric power plants, solar power energy systems, geothermal facilities, and wind power systems face continuous exposure to moisture, fluctuating temperatures, airborne contaminants, and harsh chemicals. If left unchecked, corrosion can lead to

Addressing Corrosion Challenges in the Mining Industry with ZERUST® Solutions

The mining industry faces persistent challenges from corrosion, which is a natural degradation process exacerbated by harsh environments. Consequently, corrosion impacts equipment, safety, and profitability. Therefore, implementing proactive solutions is essential. In addition, this blog explores how ZERUST®’s corrosion prevention and remediation products address corrosion challenges in the mining industry. Corrosion Challenges in the Mining

Corrosion Control for Control Rooms and Electronics: A Comprehensive Guide

Corrosion is a silent threat that plagues control rooms and electronics in industrial settings. As a result, it can cause circuitry failures, compromise equipment reliability, and ultimately lead to costly downtime. In this blog post, we’ll explore the challenges of corrosion control in control rooms and electronics and how innovative products like ZERUST® ActivDri™ Packets,

Axxanol™ 718-ESS vs. Conformal Coatings: Choosing the Right Corrosion Protection Solution

Corrosion protection holds key importance in electrical and electronic applications. Two common approaches for achieving this are conformal coatings (CC) and ZERUST® Axxanol™ 718-ESS, a multimetal electrical corrosion inhibitor spray. In this blog post, we’ll delve into the key differences between these two methods, their respective advantages and disadvantages, and how Axxanol™ 718-ESS stacks up

Revolutionizing the Electric Vehicle Market with VCI: Vapor Corrosion Inhibitors

Welcome to our comprehensive guide on Vapor Corrosion Inhibitors (VCI) and their transformative impact on the Electric Vehicle (EV) market. As the worldwide leaders in Vapor Corrosion Inhibitor Technology, we pride ourselves on providing our customers with comprehensive corrosion management solutions that provide our customers with rust-free results. In this blog, we will explore the

Rust Prevention: How-to Keep Your Metal Parts Rust-Free When Shipping Containers Overseas

Scenario: You’ve recently filled a shipping container and shipped it overseas from North America to Asia. Upon arrival, your customer has complained that rust is rampant throughout the container, and you are planning to ship another container every month. Unfortunately, you can’t afford the rework and scrap costs on the most recent shipments, so what do

What to Do When Rust Prevention Fails?

In the manufacturing world, many companies go to great lengths to select products and processes to prevent rust and corrosion from forming on their valuable metal assets during transit and storage. They will probably incorporate volatile corrosion inhibitor (VCI) packaging, rust preventative (RP) coatings, desiccants, or some combination of them. But what happens when their

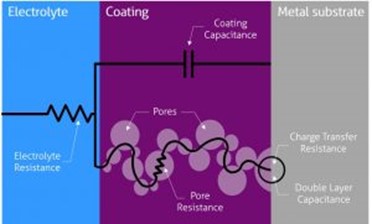

Using Electrochemical Impedance Spectroscopy (EIS) Method for a Better Understanding of the Corrosion System

The corrosion rate is controlled by different factors such as pH, temperature, electrochemical potential, electrolyte, and as well as the applied corrosion control method. Those factors together make the corrosion control method evaluation complex and time-consuming. As we all know, corrosion is an electrochemical procedure. The concept of electrical resistance tells us the higher the