How ZERUST® Products Prevent Rust in Everyday Life

Typically, when most people think of ZERUST® products, they picture them in use on factory floors, in shipping crates, or in industrial applications. And while ZERUST® has certainly made its mark protecting large-scale metal assets around the globe, its products are equally at home in everyday life. From your garage to your gun safe, your

How ZERUST® Helps in Reducing Carbon Emissions

Sustainable VCI Solutions: A Step Toward Reducing Carbon Emissions Reducing carbon emissions is a global priority. Businesses are seeking innovative solutions to minimize their environmental impact. ZERUST®, a division of Northern Technologies International Corporation (NTIC), is leading the way with sustainable Vapor Corrosion Inhibitor (VCI) technologies. These solutions extend the life of metal components, reduce

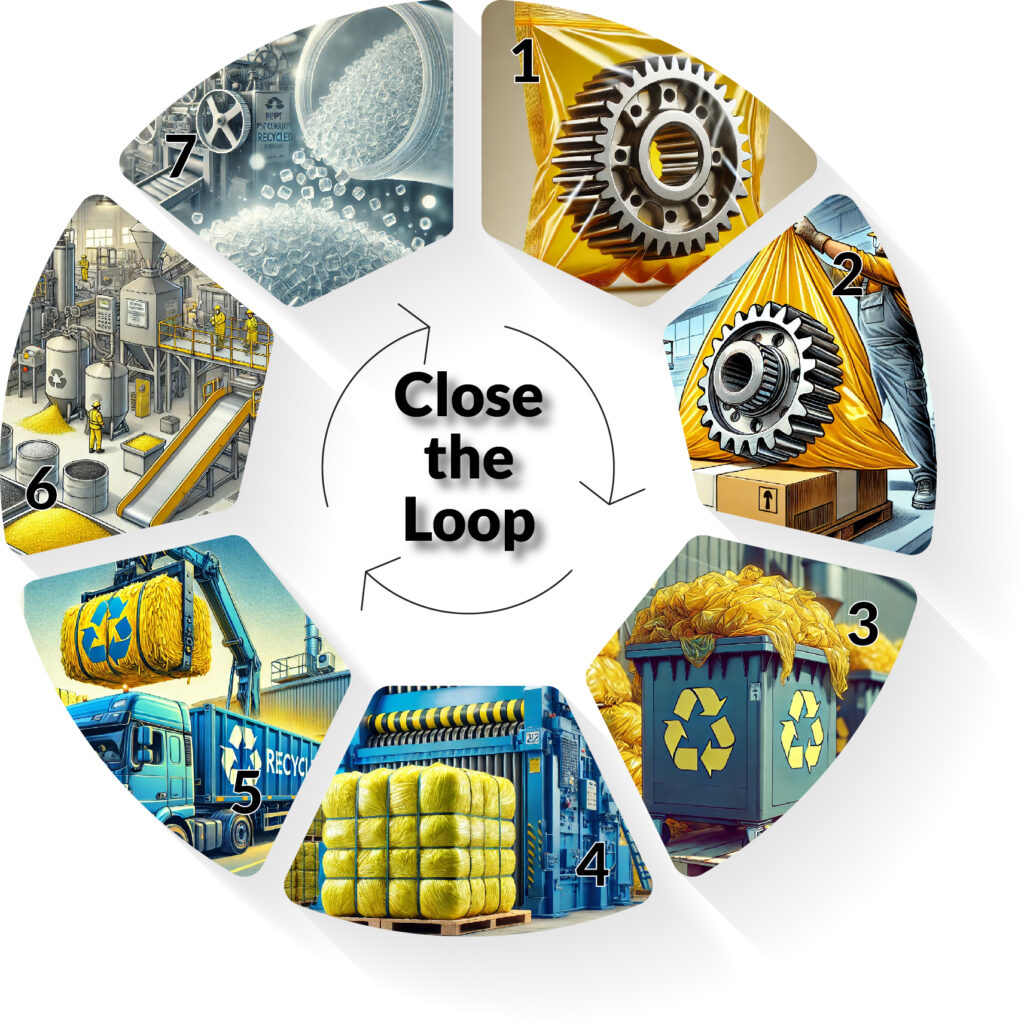

Introducing ZeCycle: A Sustainable Closed-Loop VCI Recycling Program from ZERUST® & RecycleMax®

As industries worldwide strive for sustainable manufacturing and waste reduction, companies are actively seeking circular economy solutions to minimize their environmental footprint. ZERUST®, in partnership with RecycleMax®, is excited to launch ZeCycle—a revolutionary closed-loop recycling program that transforms used ZERUST® VCI packaging into new post-consumer recycled (PCR) VCI films. Beyond Recycling: The Second Life of

Addressing Corrosion Challenges in the Mining Industry with ZERUST® Solutions

The mining industry faces persistent challenges from corrosion, which is a natural degradation process exacerbated by harsh environments. Consequently, corrosion impacts equipment, safety, and profitability. Therefore, implementing proactive solutions is essential. In addition, this blog explores how ZERUST®’s corrosion prevention and remediation products address corrosion challenges in the mining industry. Corrosion Challenges in the Mining

Comprehensive Guide to Heat Exchanger Corrosion Protection

Heat exchangers are critical components in various industries, responsible for transferring heat between fluids to regulate temperature and ensure efficient system operation. Despite their importance, these systems often operate in challenging environments where exposure to humidity, fluctuating temperatures, and corrosive chemicals can lead to significant corrosion. Corrosion issues are particularly prevalent during outdoor storage and

ZERUST® Leading the Way in Sustainable VCI Packaging with Post-Consumer Recycling

In a world where environmental consciousness is on the rise, companies are increasingly seeking innovative ways to reduce their carbon footprint and promote sustainability. One such approach that’s gaining traction is post-consumer recycling, and here at ZERUST®, we’re at the forefront of implementing this technology across our Vapor Corrosion Inhibitor (VCI) polymer packaging solutions. Furthermore,

Revolutionizing the Electric Vehicle Market with VCI: Vapor Corrosion Inhibitors

Welcome to our comprehensive guide on Vapor Corrosion Inhibitors (VCI) and their transformative impact on the Electric Vehicle (EV) market. As the worldwide leaders in Vapor Corrosion Inhibitor Technology, we pride ourselves on providing our customers with comprehensive corrosion management solutions that provide our customers with rust-free results. In this blog, we will explore the

What Is the Difference Between VCI Rolls and Sheets?

We’re commonly asked by our customers, “what is the difference between VCI Rolls and Sheets?”. So, we’ll take a quick look into VCI and the difference between the two options. VCI (Vapor Corrosion Inhibitor) packaging materials are commonly used to protect metal surfaces from corrosion during transportation and storage. These VCI poly materials work by releasing

5 Reasons the Steel Coil Industry Prefers VCI Paper and Poly for Optimal Steel Coil Corrosion Protection

Corrosion is a significant challenge in the steel coil industry, causing damage to steel coils and resulting in decreased productivity and profitability. As a result, rust-preventative coatings have commonly been used by steel coil suppliers and manufacturers to provide steel coil corrosion protection during storage and transportation. However, one solution in the steel coil industry has

What to Do When Rust Prevention Fails?

In the manufacturing world, many companies go to great lengths to select products and processes to prevent rust and corrosion from forming on their valuable metal assets during transit and storage. They will probably incorporate volatile corrosion inhibitor (VCI) packaging, rust preventative (RP) coatings, desiccants, or some combination of them. But what happens when their