Page 4 of 7

What Is the Difference Between VCI Rolls and Sheets?

We’re commonly asked by our customers, “what is the difference between VCI Rolls and Sheets?”. So, we’ll take a quick look into VCI and the difference between the two options. VCI (Vapor Corrosion Inhibitor) packaging materials are commonly used to protect metal surfaces from corrosion during transportation and storage. These VCI poly materials work by releasing

What Is the Best Rust Preventative for Your Application?

Rust is a persistent problem for metal surfaces, especially those exposed to harsh environments. If left unchecked, rust can cause significant damage and undermine the strength of metal objects. So, to safeguard against rust, it’s essential to use the right rust preventative. But with so many options available, it can be tough to determine which

5 Reasons the Steel Coil Industry Prefers VCI Paper and Poly for Optimal Steel Coil Corrosion Protection

Corrosion is a significant challenge in the steel coil industry, causing damage to steel coils and resulting in decreased productivity and profitability. As a result, rust-preventative coatings have commonly been used by steel coil suppliers and manufacturers to provide steel coil corrosion protection during storage and transportation. However, one solution in the steel coil industry has

With an Ally Like ZERUST, There Isn’t Any Rust Battle You Cannot Win

Hello to the world of rust protection. I have over 30 years of experience working as a packaging engineer in various industries and have spent the last 24 years working for a tier 1 worldwide powertrain OEM supplier. At our facility, we assembled parts and sub-components that are shipped worldwide. At our facility, a primary

Rust Prevention: How-to Keep Your Metal Parts Rust-Free When Shipping Containers Overseas

Scenario: You’ve recently filled a shipping container and shipped it overseas from North America to Asia. Upon arrival, your customer has complained that rust is rampant throughout the container, and you are planning to ship another container every month. Unfortunately, you can’t afford the rework and scrap costs on the most recent shipments, so what do

Can you use desiccants with VCI?

The short answer is “yes if used correctly.” VCI and desiccants function in different ways in reducing the risk of corrosion. VCI emits a corrosion inhibiting chemistry designed to protect the surface of the metal. Desiccant is designed to absorb atmospheric moisture, reducing the electrolyte that accelerates corrosion. VCI and desiccant do not interfere with each

What to Do When Rust Prevention Fails?

In the manufacturing world, many companies go to great lengths to select products and processes to prevent rust and corrosion from forming on their valuable metal assets during transit and storage. They will probably incorporate volatile corrosion inhibitor (VCI) packaging, rust preventative (RP) coatings, desiccants, or some combination of them. But what happens when their

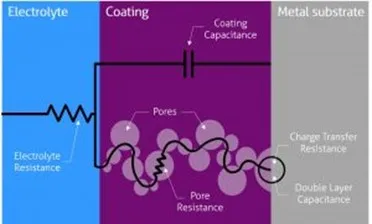

Using Electrochemical Impedance Spectroscopy (EIS) Method for a Better Understanding of the Corrosion System

The corrosion rate is controlled by different factors such as pH, temperature, electrochemical potential, electrolyte, and as well as the applied corrosion control method. Those factors together make the corrosion control method evaluation complex and time-consuming. As we all know, corrosion is an electrochemical procedure. The concept of electrical resistance tells us the higher the

What Should You Consider When Choosing a VCI Supplier?

Are you in search of a VCI supplier due to company specifications? Currently experiencing corrosion issues at your facility? or just unhappy with the products and services provided by your current VCI supplier? No matter the reason for your search, when choosing a VCI supplier, you should consider this. Is the VCI supplier reputable (ISO

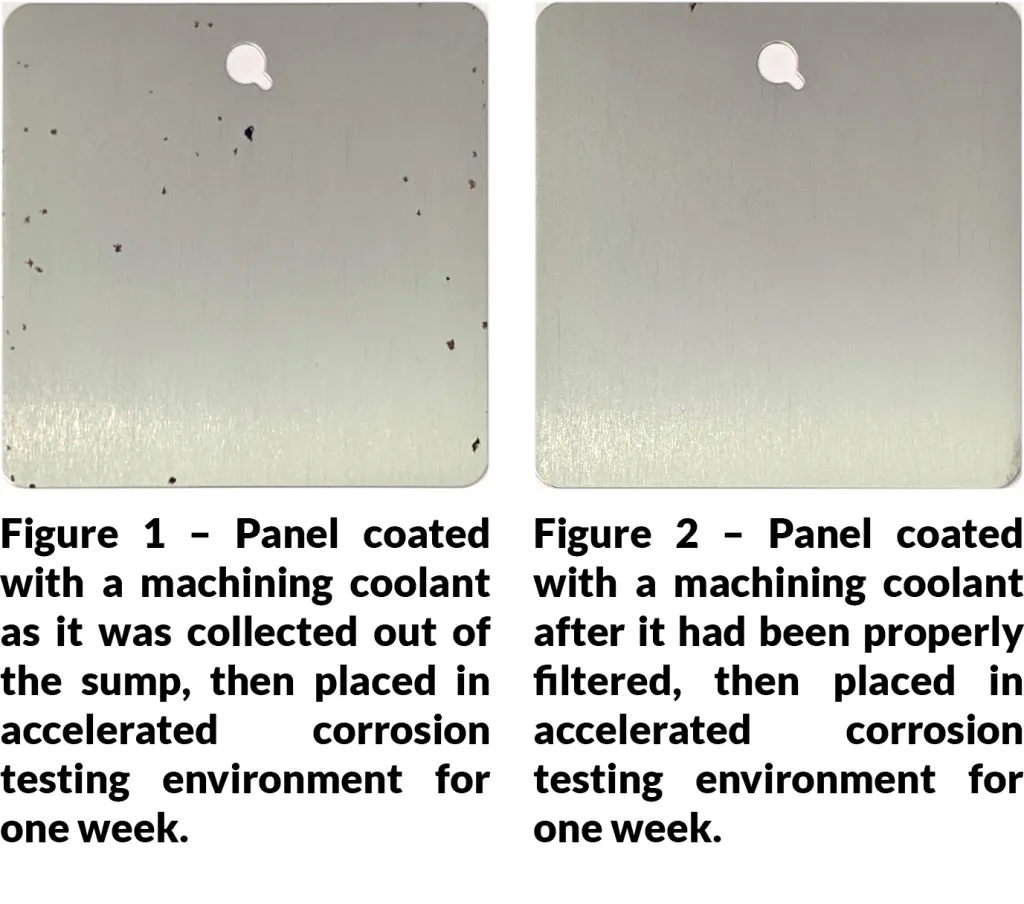

Metalworking Fluids Maintenance: Proper Filtration

Washes, rinses, machining coolants, lubricants, rust preventatives, and other metalworking fluids (MWFs) are frequently used in industrial manufacturing facilities. Proper maintenance of metalworking fluids is required to preserve the fluid’s health, increase the fluid’s lifetime, minimize corrosion risk, and even reduce wear and tear on tools and machines. Unfortunately, proper filtration is one of the