EV Corrosion Solutions for Electric Vehicle Industry

As public awareness of the effects of global climate change increases, electric vehicles (EV) continue to gain popularity across the globe. According to global EV analysis leaders at EV-Volumes, electric vehicle sales were up 62% globally in the first half of 2022 compared to the first half of 2021. Electric vehicles have advantages over traditional combustion engine vehicles, such as zero emissions, reduced running costs, increased comfort, and the absence of cooling circuits, gear shifts, and more. But even with these benefits, the shift to electric vehicles has resulted in a new set of challenges for OEMs in the Electric Vehicle Industry.

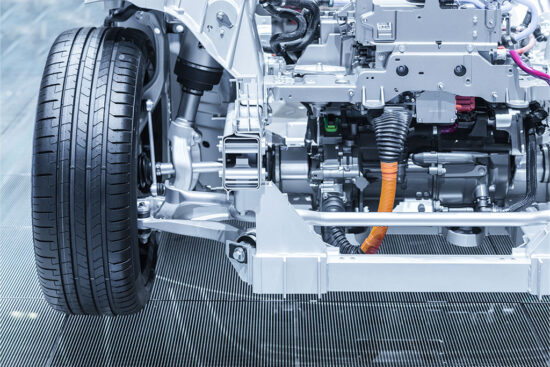

Electric corrosion has become a key focus for the Electric Vehicle Industry. The vehicle’s battery and electrical components are much more prone to corrosion as a result of being exposed to severe working conditions with increased levels of dust, dirt, moisture, and salts. More extreme temperature changes during the manufacturing, transport, and operational processes contribute to potential corrosion as well. All these factors increase the potential for EV corrosion, and thus a comprehensive corrosion management system must be implemented.

ZERUST® Vapor Corrosion Inhibitors (VCIs) Provide Corrosion Solutions for Electric Vehicle (EV) Industry

Vapor corrosion inhibitors protect against corrosion by releasing a vapor that fills the air inside a sealed container or enclosure. The vapor forms a strong bond with the metal surfaces, promoting and maintaining the natural and healthy passive oxide layer on the metal surface. This vapor forms a thin, invisible film that protects the metal from corrosion.

VCIs are often used to protect metal parts during storage or transportation. They can be especially effective at preventing corrosion in hard-to-reach areas where other forms of protection are difficult to apply. They are also useful for protecting metal surfaces that are in contact with water or other corrosive substances.

For electric vehicles, VCIs protect various metal components, such as wiring, connectors, and other electrical components, from corrosion. For example, a VCI could be used to protect metal parts during the manufacturing process, storage, and transportation. VCIs could also protect metal parts exposed to humidity or other corrosive substances while the EV is in use.

ZERUST® offers various VCI and corrosion-inhibiting products for the Electric Vehicle (EV) industry. These products range from VCI Packaging Films & Paper, VCI Emitters & Diffusers, Industrial Cleaners & Degreasers, Rust Inhibitors, and Preventatives & Coatings. ZERUST® provides cost-effective and versatile protection against Electric Vehicle corrosion damage for metals in work-in-progress, shipping, and storage.

Corrosion Inhibiting Packaging Products

- ZERUST® Multimetal VCI Film protects EV parts and components, including ferrous and non-ferrous metals, from corrosion damage during storage and shipment.

- ZERUST® Anti Tarnish Film protects silver, copper, bronze, brass, and tin from damaging oxidation and tarnish. The film works by blocking out the corrosion-causing acid gases with acid-gas scavengers before they can cause damage to metals.

- ZERUST® VCI Paper is available in a wide range of paper weights (30#, 35#, 40#, and more), protection types (ferrous, non-ferrous, and multimetal), and sizes (rolls and sheets) to provide the ideal packaging solution for your application needs. ZERUST® ICT® VCI Kraft Papers are high-quality bio-based, recyclable, biodegradable, and saturated with proven ZERUST® corrosion inhibitors.

VCI Diffusers & Emitters

- ZERUST® ActivPak®(LS) are fast-acting VCI emitter packets that protect ferrous and aluminum metals against flash corrosion in aggressive environments.

- ZERUST® ActivDriTM Moisture & Corrosion Control Packets are patent-pending, economical, effective, and easy-to-use dual action, moisture control vapor corrosion inhibitor sachet products that protect against environmental contaminants and humidity that aggressively corrode metal parts, components, electronics, and electrical components. As a result, reducing quality rejects, system reliability issues, system malfunctions, and intermittent connection errors.

- ZERUST® Vapor Capsules are portable capsules that contain patented ZERUST® VCI technology. Use Vapor Capsules to protect metals in hard-to-reach areas of control panels, electrical cabinets, and other enclosed spaces during storage, shipment, and operation.

Rust Preventatives

- ZERUST® Axxanol™ 718-ESS is a multimetal electrical corrosion inhibitor spray designed for challenging environments with acid gas vapors and humidity. ZERUST® Axxanol™ 718-ESS leaves a thin, water-displacing, non-staining, non-hardening, soft film. Axxanol™ 718-ESS can protect electronic components, electric cabinets, junction boxes, and all types of metallic sliding parts from corrosion while providing lubrication. Easy to use, suited for in-service use, and intended for indoor and short-term outdoor protection and lubrication.

- VCI Packaging Film & Paper provides effective corrosion protection and packaging combined in one step

- Metals are ready for use and assembly directly out of VCI Packaging Film & Paper

- ZERUST® offers a wide range of rust inhibitor coatings ranging from oil-based, wax-based, water-based, and grease-based to oil additives

- ZERUST® VCI Products provide safe and effective corrosion protection