ZERUST® VCI Solutions for Corrosion Prevention at Power Plants

Power plants operate in some of the most demanding environments, where equipment is exposed to extreme temperatures, high humidity, fluctuating weather conditions, and corrosive chemicals. As a result, these factors contribute to the rapid degradation of critical components, leading to costly downtime, reduced efficiency, and safety hazards. Moreover, corrosion affects all types of power generation facilities, including biomass energy plants, hydroelectric power plants, solar power systems, geothermal plants, and wind farms. To address these challenges, ZERUST® provides advanced Vapor Corrosion Inhibitor (VCI) solutions that are specifically designed to protect essential power generation equipment and extend its lifespan.

Ensuring corrosion prevention at power plants is crucial for maintaining optimal performance and avoiding unplanned maintenance. With ZERUST® corrosion protection solutions, power generation facilities can safeguard their equipment, reduce maintenance costs, and enhance operational reliability. Contact ZERUST®/EXCOR® today to implement a customized corrosion prevention strategy for your facility.

Request InformationComprehensive Corrosion Prevention at Power Plants

ZERUST® offers a full range of corrosion prevention products tailored to the unique challenges faced by power plants. Whether protecting large industrial machinery, metal structures, pipelines, or sensitive electrical components, ZERUST® VCI technology delivers long-lasting protection to ensure efficiency and durability.

Highlighted ZERUST® Products for Corrosion Prevention at Power Plants

|

Axxanol™ 707C VCI Oil AdditiveAxxanol™ 707C is a vapor-phase corrosion inhibitor (VCI) oil additive designed to protect internal surfaces within closed systems, such as gearboxes, hydraulic systems, and engines.

|

|

ZERUST® Vapor CapsulesVapor Capsules are compact and effective VCI diffusers that provide corrosion protection in enclosed spaces such as electrical control panels and cabinets.

|

|

Axxanol™ Z-Maxx SeriesAxxanol™ Z-Maxx is a high-performance anti-corrosion grease designed to protect exposed metal components from rust in extreme environments.

|

|

ZERUST® Axxanol™ Spray-GAxxanol™ Spray-G is a sprayable rust preventative grease, ideal for hard-to-reach areas on power plant equipment.

|

|

ICT®510-C VCI FilmICT®510-C VCI Film is a cost-effective corrosion prevention solution used for packaging and protecting metal components during storage and transportation.

|

|

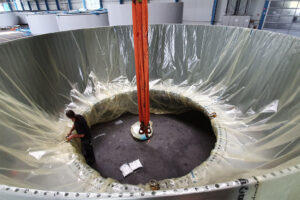

ZERUST® ICT®510-OPS Outdoor Preservation VCI Shrink FilmICT®510-OPS is a high-strength VCI shrink film designed to provide long-term outdoor corrosion protection.

|

|

AxxaClean™ Rust RemoversAxxaClean™ rust removers effectively restore corroded metal surfaces, eliminating rust and oxidation buildup.

|

|

AxxaVis™ HST-10 Hydrostatic Testing AdditiveAxxaVis™ HST-10 is a hydrostatic testing corrosion inhibitor additive that prevents internal corrosion during hydrostatic pressure testing, protecting pipelines and heat exchangers.

|

Benefits of ZERUST® Products for Corrosion Prevention at Power Plants

ZERUST® solutions provide reliable, long-term corrosion prevention at power plants, offering numerous benefits:

- Extended Equipment Lifespan: Protects turbines, pipelines, gearboxes, and structural components, ensuring years of reliable performance.

- Reduced Maintenance Costs: Minimizes unplanned downtime and costly repairs, keeping power plants running efficiently.

- Enhanced Operational Reliability: Prevents moisture damage and rust-related failures in control systems and electrical enclosures, which helps maintain consistent performance.

- Versatile Protection: Suitable for biomass, hydroelectric, solar, geothermal, and wind power plants, so it effectively protects various metal types and components.

- Eco-Friendly & Compliant: ZERUST® products meet global environmental regulations, including RoHS and REACH compliance, ensuring sustainable solutions.

- Easy to Apply & Remove: Sprayable coatings, VCI packaging, and vapor capsules allow for quick and hassle-free protection.

- Effective in Harsh Conditions: Works in extreme temperatures, high humidity, salt-laden air, and corrosive chemical environments.

- Corrosion Recovery Solutions: AxxaClean™ rust removers restore corroded equipment, which extends usability and reduces replacement costs.