Tanks made out of 304 and 316 stainless steel are recommended. Mild steel tanks can be used but should have good structural integrity and be maintained in good working order. Plastic and poly-lined tanks should be avoided.

ZERUST® Axxanol™ A35CD-7

ZERUST®/EXCOR® Axxanol™ A35CD-7 is a high-flash solvent-based rust preventative that forms a clear, thin, dry-to-touch film. As a result, it eliminates oily surfaces that attract dust and other contaminants.

Features

- High-flash solvent-based rust preventative results in an invisible dry-to-touch thin coating

- Displaces moisture/water on metal surfaces

- Ready-to-use product

- Easy to apply , as well as remove

- Non-staining

- Non-toxic and solvent-based

- Multimetal compatible

- Not regulated for transport

- Fully dried coating has no VOC

- May be used with ZERUST® VCI packaging

Product Description

Use ZERUST® Axxanol™ A35CD-7 high-flash solvent-based rust preventative to safely protect metal components, machined and cast parts, engines, molds, and more for up to 6 months‡ during shipment, storage, and work-in-progress. During drying, the solvent completely evaporates, leaving behind a safe dry-to-touch rust preventative coating. As a result, Axxanol™ A35CD-7 coated and dried parts are safe to handle, and end users do not need to wear personal protective equipment such as a respirator, mask, or safety glasses. However, we recommend using clean gloves without lint or talc to keep metals free of contaminants.

After application and allowing metals to completely dry, place them into ZERUST® Vapor Corrosion Inhibitor (VCI) film packaging products for a more robust solution that protects for years‡ during indoor storage or challenging shipping conditions, such as ocean freight. Axxanol™ A35CD-7 does not intentionally contain barium or heavy metals and complies with Global Automotive Declarable Substance, TSCA, RoHS, and REACH SVHC requirements.

Why Choose ZERUST®?

For over 50 years, beginning with the invention of Vapor Corrosion Inhibiting (VCI) film, ZERUST® has led the market in quality corrosion solution products. Furthermore, we dedicate ourselves to providing expert corrosion management services and further adding solutions for our customers. In addition, ZERUST® users have access to on-site support from ZERUST®/EXCOR® representatives in more than 70 countries. As a result, our customers have peace of mind when they choose ZERUST® for corrosion control management.

Availability

ZERUST®/EXCOR® Axxanol™ A35CD-7 is sold as a ready-to-use liquid product. For further ordering information, contact your ZERUST®/EXCOR® representative.

| Part Number | Quantity | Protection | |

|---|---|---|---|

| 350-M-00091PL | 5 Gallons | Multimetal | |

| 350-M-00091DR | 55 Gallons | Multimetal |

Frequently Asked Questions

ZERUST® has a full line of cleaner products (e.g., AxxaWash™ KF-121, KF-123, KF-124, etc.) that are compatible or even work synergistically with Axxanol™ A35CD-7. Before combining Axxanol™ A35CD-7 with any non-ZERUST® wash solution, a compatibility test should be performed.

ZERUST® offers a complete line of VCI packaging products (e.g., ICT®420, ICT®510, ICT®520, etc.) that are compatible or work synergistically with Axxanol™ A35CD-7. However, ZERUST® has not completed any compatibility tests with any non-ZERUST® VCI packaging products, so it’s recommended that the end-user performs their own compatibility tests before combining Axxanol™ A35CD-7 with any non-ZERUST® VCI packaging.

Yes. However, the surface temperature should be lower than 140°F (60°C).

No, when Axxanol™ A35CD-7 is used as prescribed and coated parts are stored indoors or as part of corrosion protection for export parts packaged in boxes, crates, VCI packaging, and/or UV-resistant packaging; Axxanol™ A35CD-7 does not stain the metal surface.

No, there are components in Axxanol™ A35CD-7 that do not make it conducive to paint adhesion. Therefore, it’s recommended that the Axxanol™ A35CD-7 coating is removed with ZERUST® AxxaWash™ products (e.g., AxxaWash™ KF-121, KF-123, KF-124, etc.) or commercial alkaline cleaners prior to painting.

The Axxanol™ A35CD-7 coating may be removed using ZERUST® AxxaWash™ cleaners (e.g., AxxaWash™ KF-121, KF-123, KF-124, etc.) or any commercial alkaline cleaners.

For optimum protection and best practice, it’s highly recommended that the Axxanol™ A35CD-7 coated parts be completely dried before being placed inside any packaging or container. Axxanol™ A35CD-7 has been tested to be compatible with ZERUST® VCI packaging and plain plastic packaging. Test before using any other types of non-ZERUST® VCI packaging (See packaging guidelines).

The corrosion protection provided by both applications is identical. However, immersion application for Axxanol™ A35CD-7 is recommended when large quantities of small parts are processed or when parts have holes, slots, internal surfaces, etc., that spray applications cannot reach. If applied by spray, additional cleaning benefit is seen due to spray impingement. However, you should ensure proper draining of the excess product and completely dry the coating to avoid any sticky residue on the part’s surface.

Axxanol™ A35CD-7 is designed to provide up to 6 months‡ of indoor storage protection, depending on warehouse conditions (Temperature, RH), without additional packaging. For long-term protection, you may place or wrap the clean and dry parts with the use of ZERUST® ICT®510-C VCI bags and/or films for long-term (years)‡ corrosion protection, such as export shipment or inventory storage (See ZERUST® VCI Packaging Guidelines).

Yes, a circulating pump is required, and the flow rate is tank size-dependent. Typical tank turnover rates should be 3x -5x per hour. For example, a 100-gallon tank should have a pump sized with a minimum flow rate of 300 – 500 gph (gallons per hour) or 5 – 8.33 gpm (gallons per minute).

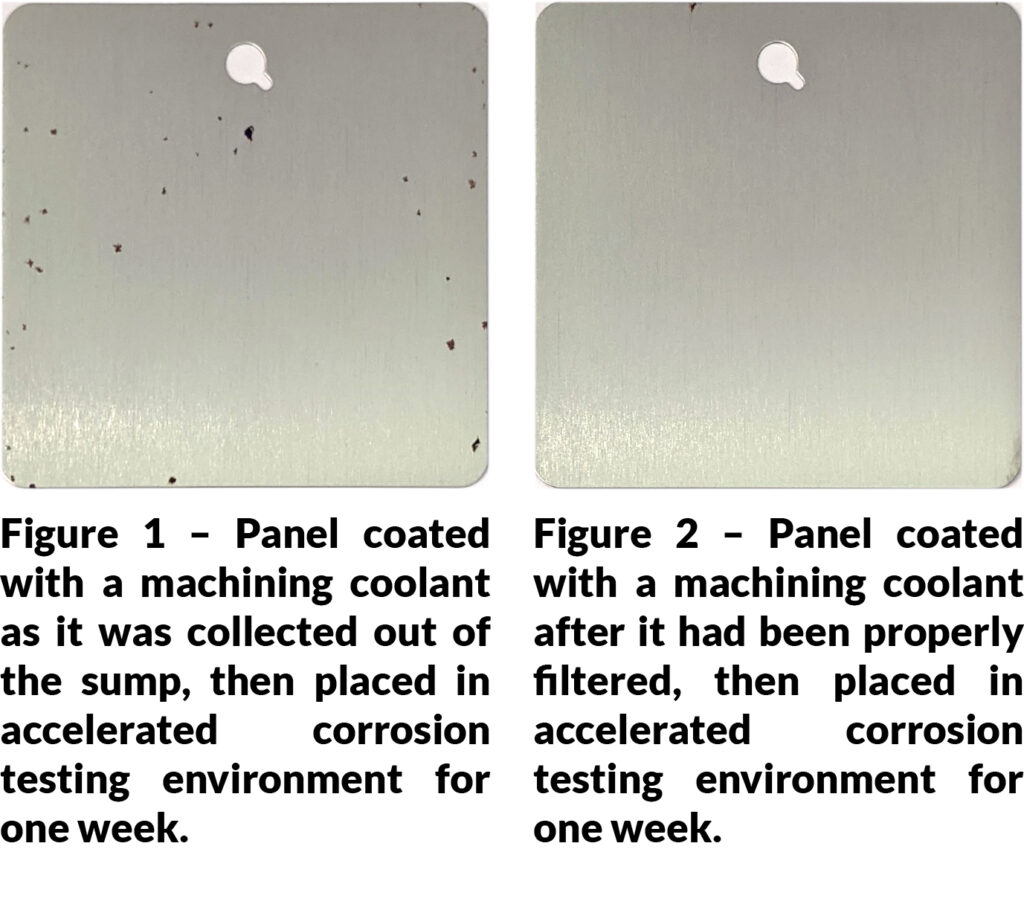

A filtration system is always recommended, and the filter porosity is dependent on the customer’s cleanliness level requirement. A typical filter media size is 25 to 50 microns. However, it is recommended to use a 5-micron stainless steel reusable filter, such as available from www.homebrewit.com. Home Brew It is not endorsed by, directly affiliated with, or sponsored by ZERUST®/NTIC.

No, parts coated with Axxanol™ A35CD-7 that are fully dried do not have any VOC. VOC is present in the ready-to-use Axxanol™ A35CD-7 product. However, when the coating fully dries on the part’s surface, the VOCs evaporate.

Axxanol™ A35CD-7 coated 1/8” cold rolled steel plates were successfully stick welded together. However, some brown/ black carbonization residue was noticed and was not easily removed from the surface. Good welding practices are to scrub, sand, or wire brush the areas to be welded, which would remove Axxanol™ A35CD-7 from the area.

At a temperature of 635°F (335°C), 99% of Axxanol™ A35CD-7 was burned off. Therefore, we do not anticipate any negative impact on the heat treatment process under ideal conditions. However, for best practice, we recommend testing before use or washing off Axxanol™ A35CD-7 with a ZERUST® wash solution (e.g., AxxaWash™ KF-121, KF-123, KF-124, etc.) before heat treatment.

Axxanol™ A35CD-7 contains a high-flash solvent. Therefore, drying/solvent evaporation times are highly dependent on temperature and humidity. Axxanol™ A35CD-7 typically dries in roughly one hour at 70°F (21°C). You may accelerate drying by placing parts in an oven at no more than 140°F (60°C) for 10 – 15 minutes or under a mechanical fan or air knife for ~ 30 minutes. If a fan or air knife is used, clean filtered air should be utilized to prevent debris and/or contaminations from attaching to the surface.

There are several efficient ways to reduce evaporative losses in a tank, including; Minimizing the entry opening by using a narrower dip cage, adding walls around the dip tank opening, using floating polypropylene balls to reduce liquid surface exposure, and avoiding a direct suction fan over the immersion tank, etc.

Yes, Axxanol™ A35CD-7 may be reapplied to the parts. As always, it’s recommended that the parts be clean and free from debris, oil, or other contaminations before reapplying. NOTE: The reapplication of Axxanol™ A35CD-7 won’t reverse any corrosion that already exists.

No, the Axxanol™ A35CD-7 product has expired and may not provide the intended corrosion protection performance.

Email sds@ntic.com to request the Safety Data Sheet for Axxanol™ A35CD-7 and/or all other ZERUST® products.

Request Information

Please complete the form below to request a sample or information. A ZERUST® representative will review your request and reply within 1 business day.

Related Products

-

Axxanol™ A35CD-32 is a solvent-based, non-staining rust preventative that forms a clear, thin, near dry-to-touch RP film. As a result, it provides powerful corrosion protection against aggressive environments, such as salt air and humidity.

-

Axxanol™ 33 is a rust preventative oil that forms a light oily film, providing powerful corrosion protection against aggressive environments such as salt air and humidity.

-

Axxanol™ 46-BIO is a sprayable bio-based rust preventative oil that forms a thin, transparent, non-tacky film that’s also a light lubricant oil.

-

Axxanol™ 34CD is a solvent-based coating that forms a very light, oily, near dry-to-touch rust preventative film that provides powerful corrosion protection against aggressive environments.

-

Axxanol™ 750 is a rust prevention spray containing Vapor Corrosion Inhibitors (VCI). When shipped or stored in enclosed packaging, Axxanol™ 750 forms a clear, thin, oily film that provides a moisture barrier and contact inhibitor with ZERUST® VCI chemistry that migrates to metal surfaces in hard-to-reach voids, crevices, and chambers, providing powerful corrosion protection.

-

Axxanol™ 750-NV is a rust preventative oil that forms a clear, thin, oily film on the metal surface, providing a moisture barrier and powerful corrosion protection against aggressive environments such as salt air and humidity.

-

Axxanol™ Spray-G is a sprayable rust preventative grease that provides the protection of a grease in the convenience of a sprayable form. It’s designed to protect metal parts, equipment, and assemblies during long-term indoor and outdoor storage and challenging overseas shipping applications where a removable coating is essential.

-

Axxanol™ Z-Maxx Anti-Corrosion Grease Series consists of two products, Axxanol™ Z-Maxx and Z-Maxx LV. Z-Maxx is a thick NLGI 2 grease and is also offered as a lower viscosity (LV) NLGI 0 grease that is designed for spreadability and light lubrication properties.

-

Axxatec™ 80C is a water-based liquid concentrate rust preventative designed to provide long-lasting protection during indoor storage, shipping, and assembly.

-

Axxatec™ 8110C is an easy-to-use water-based corrosion-inhibiting additive for the protection of interior surfaces and parts comprised of iron, steel, aluminum, copper, and brass within closed systems.

-

Axxatec™ 85-F is a ready-to-use water-based VCI rust preventative liquid designed for fogging and spraying applications. It protects ferrous metals using ZERUST® contact inhibitors and proven Vapor Corrosion Inhibitor (VCI) technology.

-

Axxatec™ 87-M is a ready-to-use foggable water-based rust preventative designed for fogging and spraying applications. It protects ferrous metals using ZERUST® contact inhibitors and proven Vapor Corrosion Inhibitor (VCI) technology and is multimetal compatible.

-

AxxaVis™ HST-10 powder additive is an effective hydrostatic testing corrosion inhibitor that treats water used to test pressure vessels and voids. It reduces hardness and deactivates ionic contaminants like chlorides found in municipal water sources, preventing rust and hard water deposits on metals.

-

AxxaVis™ PX-05-AN is a powder that, when added to rinse water, enables it to neutralize acids left by cleaning processes. Use to control flash corrosion on metals caused by acids left over from cleaning and rust removal treatments, such as ZERUST® AxxaClean™ rust removers.

-

AxxaVis™ PX-10-HRD is a powder metalworking fluid additive that conditions hard water when deionized water is unavailable. Use to treat tap water with a hardness of up to 700 ppm CaCO3 and prevent scale and scum. In addition, it increases the performance of ZERUST® products that require dilution, such as Axxatec™ and AxxaWash™ concentrates.

-

Axxanol™ A35CD-32 is a solvent-based, non-staining rust preventative that forms a clear, thin, near dry-to-touch RP film. As a result, it provides powerful corrosion protection against aggressive environments, such as salt air and humidity.

-

Axxanol™ 33 is a rust preventative oil that forms a light oily film, providing powerful corrosion protection against aggressive environments such as salt air and humidity.

-

Axxanol™ 46-BIO is a sprayable bio-based rust preventative oil that forms a thin, transparent, non-tacky film that’s also a light lubricant oil.

-

Axxanol™ 34CD is a solvent-based coating that forms a very light, oily, near dry-to-touch rust preventative film that provides powerful corrosion protection against aggressive environments.