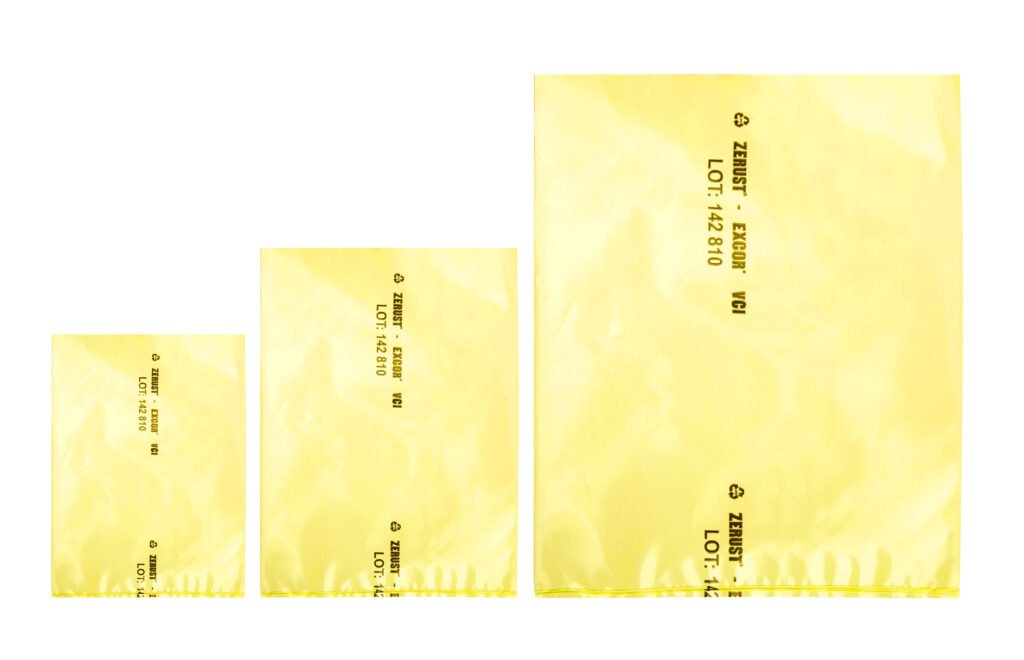

Who?

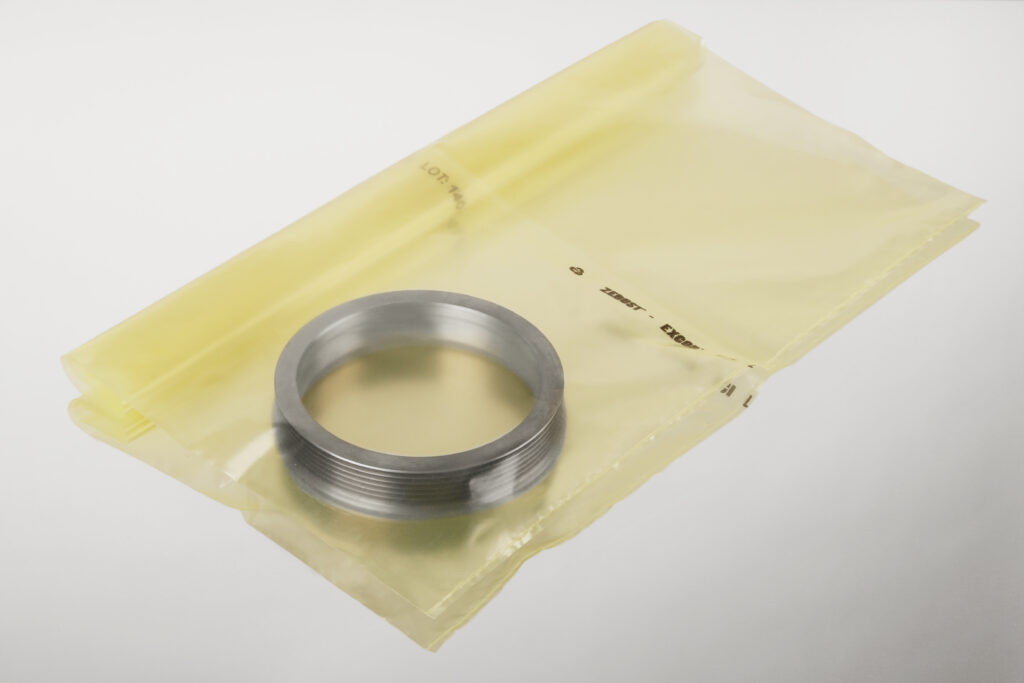

Tier 1 automotive powertrain manufacturer

What?

Producing new part and need a streamlined VCI film bag solution

Why?

Easier for their employees to pack and close the VCI film bags, allowing them to save on time and material cost

How?

Local ZERUST® representative visited the customer’s facility to measure the tote used for their new part, and a new optimal VCI film bag size was calculated