Who?

Leading auto parts manufacturer

What?

Corrosion prevention for shipment of parts

Why?

Reduce packaging and labor cost

How?

ZERUST® ICT® 520-CSL Cold-Adhesive VCI Film packaging eliminates need for time-intensive wrapping methods

Leading auto parts manufacturer

Corrosion prevention for shipment of parts

Reduce packaging and labor cost

ZERUST® ICT® 520-CSL Cold-Adhesive VCI Film packaging eliminates need for time-intensive wrapping methods

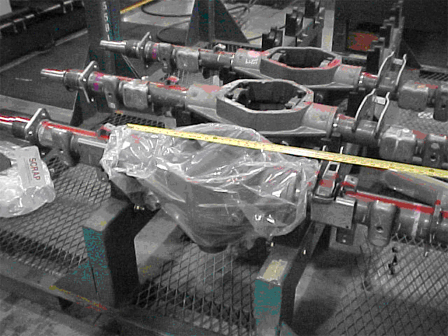

A leading manufacturer of axles and other automotive parts wanted to find a faster, more efficient corrosion inhibiting packaging solution to protect gears, axles, and differential units during service and inter-plant shipment. Typically, these parts are wrapped with VCI film and secured with tape. However, this process is very labor intensive, taking an average of four minutes to wrap and tape a single part.

ZERUST® recommended ICT®520-CSL Cold-Adhesive VCI Film to save them time and prevent corrosion. ZERUST® ICT®520-CSL is a cold-adhesive VCI film that bonds to itself, creating a self-adhesive closure that takes seconds to complete. The cold adhesive allows the package to be closed through pressure alone and not through the introduction of heat, staples, or tape.

The manufacturer tested ZERUST® Cold-Adhesive VCI Film on their large gears and differential units and was astonished at how fast and easy it was to use! They also liked the visibility of the part through the transparent film. The cold seal package took less than one minute to complete, compared with four minutes for the VCI film and tape – a 75% savings in packaging time! Realizing how much they could save in labor costs, the manufacturer decided to completely replace their VCI film and tape operation with ZERUST® ICT®520-CSL Cold-Adhesive VCI Film. Contact a ZERUST® Representative for a comprehensive corrosion management solution most effective for your metal assets.